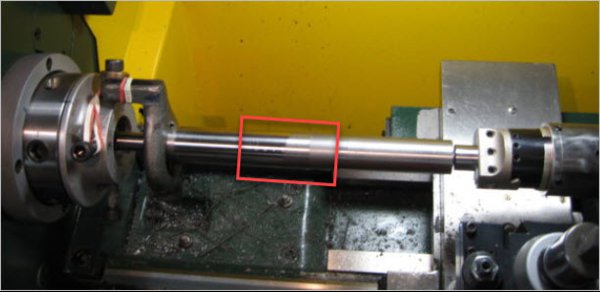

The MT3 arbor is tangless. At first I had the same question and made a sleeve to lock the boring head to the quill.

After some tests it did not seem to be a problem. The MT3 taper holds very well on its own and was actually very difficult to eject from the quill.

The MT3 taper seemed to be less torqued than during some drilling operations. There is little offset and cuts are relatively light so the MT3 taper has an easy time of it. Of course the MT3 socket andarbor are in excellent condition. I do not use the locking sleeve anymore.

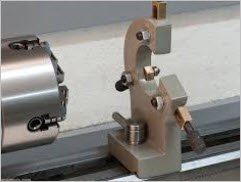

A more obscure cconcern is the boring head unscrewing on its arbor. A set screw was added on mine as can be seen in the first picture above.

After some tests it did not seem to be a problem. The MT3 taper holds very well on its own and was actually very difficult to eject from the quill.

The MT3 taper seemed to be less torqued than during some drilling operations. There is little offset and cuts are relatively light so the MT3 taper has an easy time of it. Of course the MT3 socket andarbor are in excellent condition. I do not use the locking sleeve anymore.

A more obscure cconcern is the boring head unscrewing on its arbor. A set screw was added on mine as can be seen in the first picture above.

Last edited: