- Joined

- Nov 16, 2012

- Messages

- 5,596

Thanks Ray. I'm still not getting how you could travers cut through the cathead area (or maybe that's just not possible & I'm still not getting it). I figured if an open frame steady had tangent contact points like sketch of cross section, you might get away with it. Although you would still have to reset the fingers with every cut.

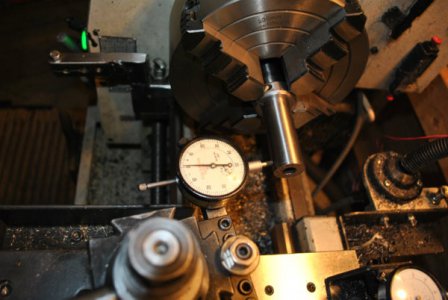

There's a steady rest and a follower-rest which are 2 different things. Your picture is showing what a follower rest does. Those attach to the carriage and support the spinning shaft and follow along as you cut. That works fine for a non-tapered shaft. When the shaft is tapered the diameter is constantly changing and the follower will not self-adjust itself to remain in proper contact.

You cannot traverse the cut on either side of a steady rest. You can work on the left or right side and to switch sides, you have to break the setup and re-establish it.

On a tapered shaft, if you're going to use a stead rest, you need to use a cathead to proved a flat surface for the bearings or contact pads to ride on. There are problems with this too... you have to grind flats where the cathead bolts will touch otherwise, the grip won't hold (for long).

Either way, yes, you're left with an unfinished spot that has to be smoothed over. That is where that tapered-bore shaft comes into play.

Ray C.