I had such a great morning, I thought I would tackle another detail. I noticed I forgot to make the spring loaded index pin for the tool holder. I should have left well enough alone. I put a 1 inch square piece of steel 2 inches long in the lathe, turned the end to fit the hole in the index shield plate. then drilled the holes for the pin. thing is looking good. I put it in the mill to cut it down and fancy it up a bit. All this took about an hour. I took photos but they got lost somewhere, I can't find them. Everything is perfect so far, then I put it in the drill press to drill the two mounting bolt holes and everything went to doo-doo from there. I drilled the holes from the bottom and when I turned it turned over, the holes were out of line. The part tipped a little in the vise while drilling and angled the one hole. Aside from a cosmetic problem it is fine , but I have to decide if that is acceptable. After looking at it , I thought, No one will even notice this ..... or will they ( the problem with a perfectionist is nothing is good enough so he can't get anything done because he keeps doing it over).

I next made the index pin and that came out fine (hard to mess that up). found some springs to fit and I am ready to go. I put it in place on the side of the tool holder and marked the 6-32 bolt holes. drilled them and began tapping them and then I heard it ...... SNAP!!!!!........... THE TAP BROKE OF IN MY TOOL HOLDER. I thought this thing is ruined and I will have to start over and make a new one. ( that is the closest I came to crying in a long time).

( that is the closest I came to crying in a long time). I tried but the piece of tap was stuck hard in that aluminum tool holder body. I let it go for a while and then came back and took it to the shop, put it in my vise, found a 1/8" diameter carbide burr, took the burr and my hammer and BEAT THAT TAP THROUGH THE BODY. Amazingly there was minimal damage. I found out what happened.... I drilled the tap hole about 4 sizes too small ( all them little drill bits look the same).

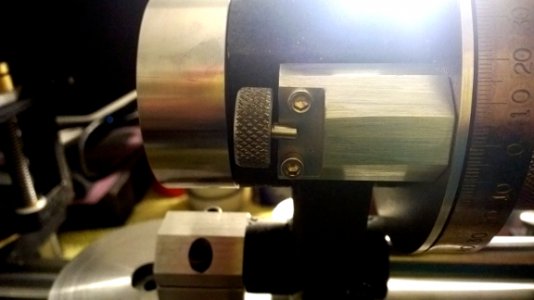

I tried but the piece of tap was stuck hard in that aluminum tool holder body. I let it go for a while and then came back and took it to the shop, put it in my vise, found a 1/8" diameter carbide burr, took the burr and my hammer and BEAT THAT TAP THROUGH THE BODY. Amazingly there was minimal damage. I found out what happened.... I drilled the tap hole about 4 sizes too small ( all them little drill bits look the same).  I tapped the holes (after re drilling) and amazingly I got a few good threads in that hole. I installed the index pin and it looks good, not perfect but good. I'm happy with it anyway

I tapped the holes (after re drilling) and amazingly I got a few good threads in that hole. I installed the index pin and it looks good, not perfect but good. I'm happy with it anyway

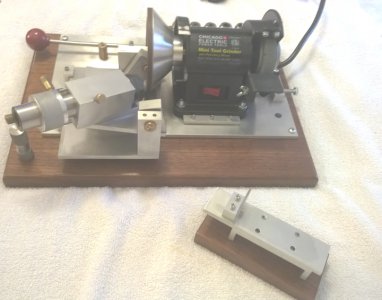

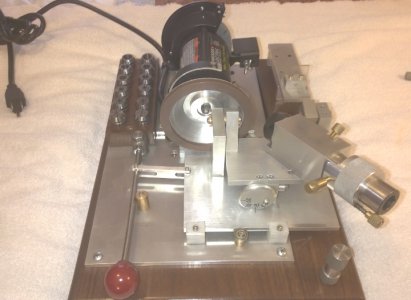

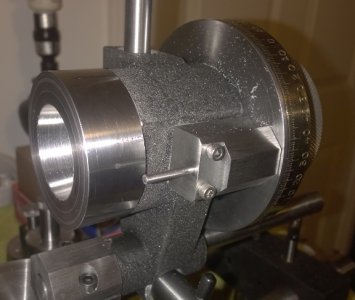

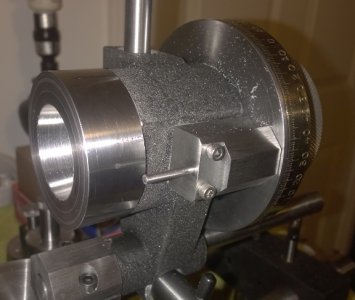

Unfortunately these are the only photos. All the photos I took making it are lost and I can't seem to find them. And before you say it , yes , it needs a knob on it ....Tomorrow.

Unfortunately these are the only photos. All the photos I took making it are lost and I can't seem to find them. And before you say it , yes , it needs a knob on it ....Tomorrow.

I don't think there is anything left to do on the tool holder.

I next made the index pin and that came out fine (hard to mess that up). found some springs to fit and I am ready to go. I put it in place on the side of the tool holder and marked the 6-32 bolt holes. drilled them and began tapping them and then I heard it ...... SNAP!!!!!........... THE TAP BROKE OF IN MY TOOL HOLDER. I thought this thing is ruined and I will have to start over and make a new one.

( that is the closest I came to crying in a long time).

( that is the closest I came to crying in a long time). I tried but the piece of tap was stuck hard in that aluminum tool holder body. I let it go for a while and then came back and took it to the shop, put it in my vise, found a 1/8" diameter carbide burr, took the burr and my hammer and BEAT THAT TAP THROUGH THE BODY. Amazingly there was minimal damage. I found out what happened.... I drilled the tap hole about 4 sizes too small ( all them little drill bits look the same).

I tried but the piece of tap was stuck hard in that aluminum tool holder body. I let it go for a while and then came back and took it to the shop, put it in my vise, found a 1/8" diameter carbide burr, took the burr and my hammer and BEAT THAT TAP THROUGH THE BODY. Amazingly there was minimal damage. I found out what happened.... I drilled the tap hole about 4 sizes too small ( all them little drill bits look the same).

Unfortunately these are the only photos. All the photos I took making it are lost and I can't seem to find them. And before you say it , yes , it needs a knob on it ....Tomorrow.

Unfortunately these are the only photos. All the photos I took making it are lost and I can't seem to find them. And before you say it , yes , it needs a knob on it ....Tomorrow.I don't think there is anything left to do on the tool holder.

Last edited by a moderator: