-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Starting cap

- Thread starter cowboychuck

- Start date

- Joined

- Feb 13, 2017

- Messages

- 2,128

Motor theory is a complex subject. Even when taught in technical schools, only a miniscule part is conveyed. As much because the instructors and texts don't fully understand it at the working level. I've gotten wound up on the subject several times in the past, and there are references linked in this database on the subject. The information is there, but to put it to practical use requires that undefineable grasp of what it means.

Then the subject of capacitors, a whole 'nuther ball of wax. It helps to have a founding in electronics to grasp caps. Then combine the two and you have a well of almost infinate depth. It can take years of working with them to grasp some of the finer details. I have 50 plus years experience and still only grasp a small part of it.

In any case, to the original question: A motor capacitor has two distinct ratings. Voltage and Capacity. . . Voltage is simple, use the highest that will fit in the can. For a 120 volt motor, try for 300 volts or better.Sometimes you can and sometimes you can't. But try. Higher voltage is a safety factor, It may never (hopefully) be needed. But if it is, it's there. Cheap insurance. . .

Capacity is a rather fluid measure. Most non-polarized (AC) capacitors will be rated as "plus or minus" some nominal amount. The tighter this tolerance the better the quality of the capacitor. A motor cap of a nominal 300 MFD (micro-farads) is about the middle of the range. Try to maintain that rating. The motor will run if the cap is above or below that nominal value. But torque will be lost for starting, with a loss either above or below the rating.

For machine tools, this doesn't really matter so much. But there are motors that start under load and capacity does matter. Machine tools usually start at almost a freewheeling load and the capacitor is switched out within a second or two. During that two seconds, the capacitor combines with the reactance of the start winding to create a second, magnetically offset, second phase. It is this two phase application that produces the torque until the motor speed reaches about half way.

This phenomanon can be observed in single phase, two phase, or three phase motors where a phase is disabled for some reason. Even a 100 HP, 3 phase motor can be started when one phase is open. It won't have much torque but will run unloaded simply by starting by hand. From here the rabbit hole goes deep. Try to better the voltage where possible and keep the capacity (MFD) as near original as possible.

.

Then the subject of capacitors, a whole 'nuther ball of wax. It helps to have a founding in electronics to grasp caps. Then combine the two and you have a well of almost infinate depth. It can take years of working with them to grasp some of the finer details. I have 50 plus years experience and still only grasp a small part of it.

In any case, to the original question: A motor capacitor has two distinct ratings. Voltage and Capacity. . . Voltage is simple, use the highest that will fit in the can. For a 120 volt motor, try for 300 volts or better.Sometimes you can and sometimes you can't. But try. Higher voltage is a safety factor, It may never (hopefully) be needed. But if it is, it's there. Cheap insurance. . .

Capacity is a rather fluid measure. Most non-polarized (AC) capacitors will be rated as "plus or minus" some nominal amount. The tighter this tolerance the better the quality of the capacitor. A motor cap of a nominal 300 MFD (micro-farads) is about the middle of the range. Try to maintain that rating. The motor will run if the cap is above or below that nominal value. But torque will be lost for starting, with a loss either above or below the rating.

For machine tools, this doesn't really matter so much. But there are motors that start under load and capacity does matter. Machine tools usually start at almost a freewheeling load and the capacitor is switched out within a second or two. During that two seconds, the capacitor combines with the reactance of the start winding to create a second, magnetically offset, second phase. It is this two phase application that produces the torque until the motor speed reaches about half way.

This phenomanon can be observed in single phase, two phase, or three phase motors where a phase is disabled for some reason. Even a 100 HP, 3 phase motor can be started when one phase is open. It won't have much torque but will run unloaded simply by starting by hand. From here the rabbit hole goes deep. Try to better the voltage where possible and keep the capacity (MFD) as near original as possible.

.

- Joined

- Oct 8, 2022

- Messages

- 13

thank you for your reply, The motor i have is a single phase 120/240 volt, so if i use a 240 volt 300 mfd cap i would be in a better position?Motor theory is a complex subject. Even when taught in technical schools, only a miniscule part is conveyed. As much because the instructors and texts don't fully understand it at the working level. I've gotten wound up on the subject several times in the past, and there are references linked in this database on the subject. The information is there, but to put it to practical use requires that undefineable grasp of what it means.

Then the subject of capacitors, a whole 'nuther ball of wax. It helps to have a founding in electronics to grasp caps. Then combine the two and you have a well of almost infinate depth. It can take years of working with them to grasp some of the finer details. I have 50 plus years experience and still only grasp a small part of it.

In any case, to the original question: A motor capacitor has two distinct ratings. Voltage and Capacity. . . Voltage is simple, use the highest that will fit in the can. For a 120 volt motor, try for 300 volts or better.Sometimes you can and sometimes you can't. But try. Higher voltage is a safety factor, It may never (hopefully) be needed. But if it is, it's there. Cheap insurance. . .

Capacity is a rather fluid measure. Most non-polarized (AC) capacitors will be rated as "plus or minus" some nominal amount. The tighter this tolerance the better the quality of the capacitor. A motor cap of a nominal 300 MFD (micro-farads) is about the middle of the range. Try to maintain that rating. The motor will run if the cap is above or below that nominal value. But torque will be lost for starting, with a loss either above or below the rating.

For machine tools, this doesn't really matter so much. But there are motors that start under load and capacity does matter. Machine tools usually start at almost a freewheeling load and the capacitor is switched out within a second or two. During that two seconds, the capacitor combines with the reactance of the start winding to create a second, magnetically offset, second phase. It is this two phase application that produces the torque until the motor speed reaches about half way.

This phenomanon can be observed in single phase, two phase, or three phase motors where a phase is disabled for some reason. Even a 100 HP, 3 phase motor can be started when one phase is open. It won't have much torque but will run unloaded simply by starting by hand. From here the rabbit hole goes deep. Try to better the voltage where possible and keep the capacity (MFD) as near original as possible.

.

- Joined

- Feb 13, 2017

- Messages

- 2,128

A 240 volt cap will do fine. Try for a higher rating if it will fit the can. But 240 will cover later changes to line voltage.

.

.

- Joined

- Oct 8, 2022

- Messages

- 13

my motor is old but in good shape all the wiring was disconected when i got the machine so im starting from square one. The motor is a single phase 120/240 volt, im gonna wire it for 240 volts i did the continuity checks and got the ones that go together then checked resistance, now im trying to figure out how to hook up power without killing myself or smoking the motor i got four wires coming out of the motor labeled 1234 and two red wires for the cap, and four coming in 2 must be power leads and the other 2 must be f/r switch leads ,im up to my armpits in i dont know ChuckMotor starting troubles can be either a bad start cap or a problem with the internal start switch- If the motor is old

both might need attention. If replacing the cap doesn't get it, open the motor up and check the switch mechanism and contacts

-Mark

Last edited:

- Joined

- Apr 30, 2015

- Messages

- 12,451

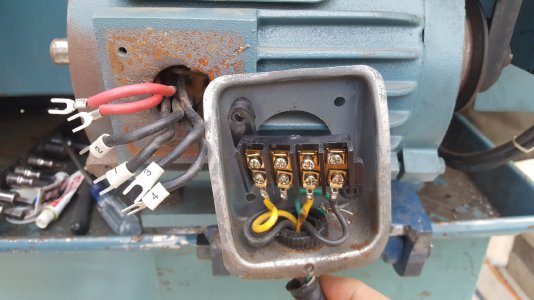

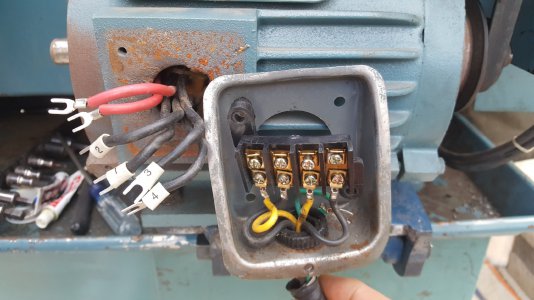

Can you show us some pictures of your electrical hardware? It would help us get you hooked up.

Motor start caps usually never see more than 120 volts even on a 240 volt configuration due to the way they arrange the start circuit

Motor start caps usually never see more than 120 volts even on a 240 volt configuration due to the way they arrange the start circuit

- Joined

- Oct 8, 2022

- Messages

- 13

- Joined

- Oct 8, 2022

- Messages

- 13

the 2 black wires are labeled u and v the yellow ones are m5 and m6, i got those labels from inside the panelCan you show us some pictures of your electrical hardware? It would help us get you hooked up.

Motor start caps usually never see more than 120 volts even on a 240 volt configuration due to the way they arrange the start circuit

Attachments

- Joined

- Oct 8, 2022

- Messages

- 13

on another note do you happen to own a 1980's 633 csi BMW?Can you show us some pictures of your electrical hardware? It would help us get you hooked up.

Motor start caps usually never see more than 120 volts even on a 240 volt configuration due to the way they arrange the start circuit

- Joined

- Apr 30, 2015

- Messages

- 12,451

Will take a look tomorrow- till then... does the machine have a control box with contactors, transformer, etc.? Picture of that would be good also

Used to own a 1984 633csi, good freeway car

Had to let it go

Used to own a 1984 633csi, good freeway car

Had to let it go

Similar threads

- Replies

- 33

- Views

- 2K

- Replies

- 12

- Views

- 1K

- Replies

- 11

- Views

- 629

- Replies

- 7

- Views

- 427