If you want to try out the TTS, for similar money you can get

this ER20 collet set.

They also have ER11, 16, 25, and 32 available. Can also get them with the TTS ATC groove for a bit more money. They aren't all listed on the ebay site, so send them an email - they responded to me within 8 hours. Shipping is a little steep but it's FAST. I'm very, very pleased with the quality.

Then pick up a JT33 drill arbor and maybe one of the 0-1/4" chuck &arbor combos from Little Machine Shop. Assuming you already have a 3/4" R8 collet, just grind the face down until it's flat so the TTS flanges bear against the spindle nose.

If you have a DTI or some other measuring tool with a standard shank, you can make a holder like I mentioned earlier in the thread or buy the dedicated set-screw holders a la carte.

Don't buy collet sets, just buy the sizes you need. I noticed after buying a couple of sets I really only use 1/2, 3/8, 1/4, 3/16, and 1/8. All the xx/64ths and 32nds are a waste.

Being an electrical engineer I can't imagine you'd need much help, but if you want some help with the probe wiring just let me know what BOB you have and if you're running Mach3 or what.

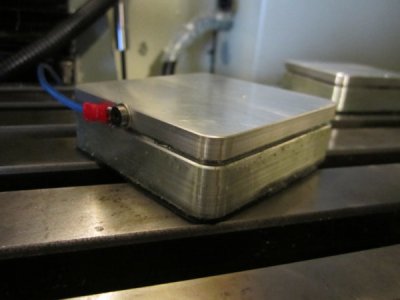

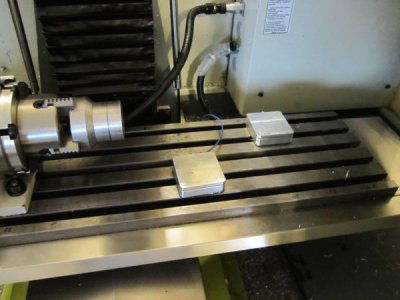

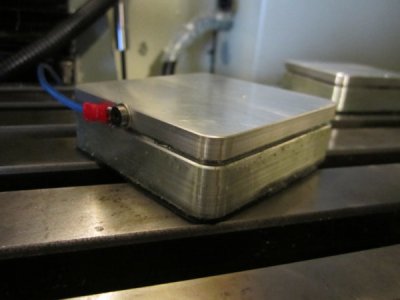

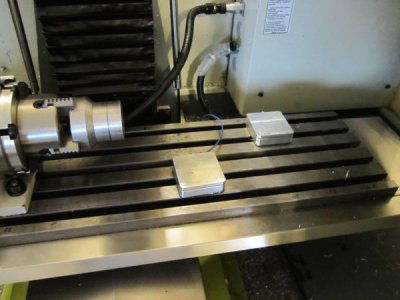

Photo of my plates below. Front plate is put on top of the part, and back plate is stationed at machine 0, 0. Jog over the moveable plate, hit the tool-zero initiate and it goes down at 50IPM and touches off. Repeat at 4IPM after a 0.025" backoff and it writes part Z 0 based on the thickness of the plate. It then moves to machine 0, 0 and does the same thing on the stationary plate and writes the difference between Z0 and the stationary plate to a register in the controller. Moveable plate is removed from part and you start machining (after setting X/Y off-sets). All tool changes in the program after the initial probe routine are touched off the stationary plate. The code pauses at M6, you switch tools and tell it go - it then probes, sets the new Z height based on the difference between the two plates, and gets on with machining.

And with this setup you don't need TTS, because your tool offset is always 0. The Z off-set is changed, but there's no tool off-set applied so you can use regular R8 collets that don't repeat when you swap them out. I just prefer to use TTS because if's fast and I want to build an ATC eventually.

Closest thing to an ATC I've ever seen. If you're running Mach3, Google & buy the "

2010 Screenset" and make yourself some touch plates. The screenset is stupid cheap for all the features and you're not dependent on everything being TTS before you start using it.