- Joined

- Apr 14, 2014

- Messages

- 3,542

I don't think you're going to have to bore it more than .010 at the most. I did a similar project many years ago when building a small end loader from scratch. I also used the same process when making fork attachments and a log splitter for the machine. In this case the pins were 1 1/4" on the log splitter frame and 1" on the loader bucket arms.

The DOM was welded into the tubes, the ends extended about 3/8" beyond the tube faces. They were ground flat, then reamed with an adjustable reamer and a shaft collar was slipped over and set screwed in place flush. The reamer was set to .005" oversize to allow grease to be pumped into the joints.

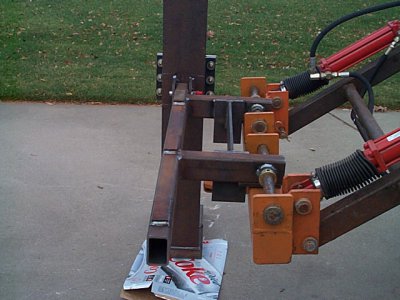

The first picture shows the pins for the hydraulic cylinders in the loader arms. The second and third pictures show the splitter carriage in pieces and partially assembled. The final picture shows the splitter carriage fitted on the machine.

The DOM was welded into the tubes, the ends extended about 3/8" beyond the tube faces. They were ground flat, then reamed with an adjustable reamer and a shaft collar was slipped over and set screwed in place flush. The reamer was set to .005" oversize to allow grease to be pumped into the joints.

The first picture shows the pins for the hydraulic cylinders in the loader arms. The second and third pictures show the splitter carriage in pieces and partially assembled. The final picture shows the splitter carriage fitted on the machine.