- Joined

- Dec 26, 2015

- Messages

- 2,157

Just to clarify, APKT type face mills will cut to a square corner, and I use them on aluminum, or when I have to cut to a square shoulder on steel. It does push the rigidity limits of the mill - demo video here in 304 stainless.

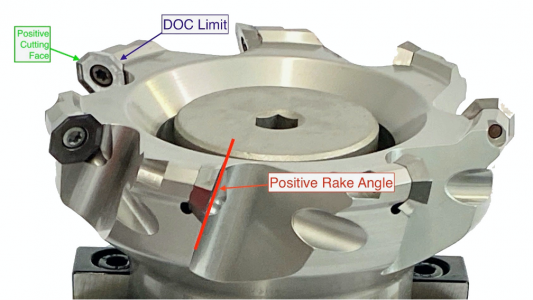

Otherwise I prefer the octagon-shaped inserts with the HAAS face mill discussed in the paper I attached to my original post in this thread. The octagon inserts have 8 cutting edges compared to the four on the SEHT/SEKT, and like the SEHT, the inserts are set at a positive rake. That Kennamental promo package mentioned by @LeeG looks like a terrific value if you can deal with a negative rake insert geometry - I hope he posts more about it after some use.

This is the 3" HAAS octagon-style face mill (they come in 2, 2.5, 3 and 4"), and for $130 is a terrific value IMO. The inserts are $90 for a pack of 10, and this SOWA R8 arbor is another $62.

Otherwise I prefer the octagon-shaped inserts with the HAAS face mill discussed in the paper I attached to my original post in this thread. The octagon inserts have 8 cutting edges compared to the four on the SEHT/SEKT, and like the SEHT, the inserts are set at a positive rake. That Kennamental promo package mentioned by @LeeG looks like a terrific value if you can deal with a negative rake insert geometry - I hope he posts more about it after some use.

This is the 3" HAAS octagon-style face mill (they come in 2, 2.5, 3 and 4"), and for $130 is a terrific value IMO. The inserts are $90 for a pack of 10, and this SOWA R8 arbor is another $62.

Attachments

Last edited: