I used vinegar, hydrogen peroxide and a little salt mixed right in a spray bottle. I boiled the parts to warm them and sprayed with the solution as soon as the water evaporated. Give everything an hour or two to rust and boil the rusty parts. Wash the oil out of fine steel wool with acetone, gently card the loose rust off and spray the warm parts again. The Emmert got 3 rounds and the Athol got 2.Turned out really nice!

Where do you get the rust bluing compound? Is this something you made, or purchased? The first time I heard of it was a LONG time ago, and have been intrigued ever since. Have a recipe, but have never actually tried it.

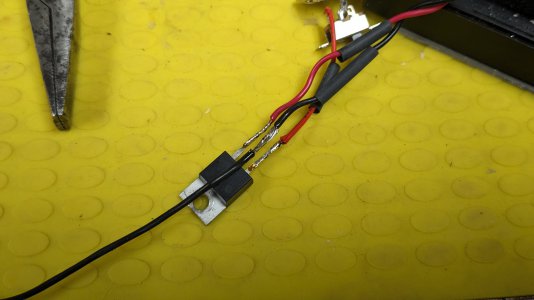

I did use Birchwood Casey Perma Blue on all of small steel hardware. I think it looks a little too blue on cast iron, the rust method ends up closer to black.

Wear rubber gloves throughout the entire process, any oil contamination will cause uneven rusting.

To finish I used, 1 part Boiled Linseed Oil to 2 parts mineral spirits applied to hot parts. Let it soak in and wipe off all the excess. I spread the used rags out on a gravel area behind my shop to safely dry.