Thanks for you attention. I loosened screws 102 and 103's but the wheel is still very hard to turn. I wonder if the bearings are too heavily preloaded?FYI, the cross slide leadscrew nut adjustment is not for adjusting the tension/resistance in the cross slide/handle, it is only to reduce the back lash in the handle/nut. It is normal to have around 0.001- 0.003" of back lash in the dial. Tightening it to the point where it is used for resistance and/or 0 back lash will prematurely wear out the nut and the leadscrew. The manual specifically states that the adjustment should be made so the cross slide moves smoothly, it should not be so tight to offer any significant resistance. This is completely different to the gibs. As you have you will most likely wear out the center portion of the leadscrew/most commonly used section and will be too tight at the extremes, and the nut will wear out much more quickly. The leadscrew nut is split in the center and the set screw drives a wedge in the center of the split to slightly tighten nut for wear. You should also recheck the backlash after you have tightened the 4 cap screws that there is at least a little backlash in the handle.

View attachment 376188

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM-1660TL

- Thread starter erikmannie

- Start date

- Joined

- Jun 12, 2014

- Messages

- 5,056

If you have a taper attachment, then it may not be aligned properly and the end bearing is too tight. I haled install one of these on the 1640 lathe, it was very heavy and a two man job. If the alignment was not spot on the it would bind. These lathes from the factory should be pretty spot on as t their specs. and tolerances, if the cross slide handle is too tight with the gibs removed then it is either the bearings or the nut. Manual on the taper attachment should be the same as the SB1263. I would speak to PM/QMT and take their direction before going further, the taper attachment is very heavy and its alignment needs to be very accurate. There were some taper dowel pins installed to set the alignment, and could be an issue with the end bearing preload.

Attachments

- Joined

- Sep 1, 2020

- Messages

- 554

Lots of feedback on your cross slide issue but you may need an expert to jump in on this comment. I have a VFD on my 1440TL and I had to fully re wire the lathe before I could get the first spindle turn. I don’t believe you can just pull 3 phase from your VFD and wire into the lathe?? Maybe that is not what you meant above? Again maybe an expert can clarify. You need to wire directly from the VFD to the motor and then set up the correct controls to test the lathe. For me that was pulling all the high voltage wiring out and re wiring control wiring back to the VFD.Now that I have the machine in place and a replacement toe jack delivered, my task tomorrow will be rough leveling the machine.

Then, figuring out how to set the parameters for the Yamaha VFD to get power to the lathe. I read posts on how others have done it, so, I hope to follow what others have suggested and done. I did read the manual. It's humongous. Initially I want 3 phase and see the spindle turn.

Thanks. I read the manual. It was a good decision to have them install it. I am reading the manual again now, to learn the names of the parts, etc., before calling PM. The cross slide wheel is hard to turn with the taper unit disengaged.The 4 hex screws on top of the cross slide & the set screw (that you previously thought was a missing screw) are used to adjust the the cross slide backlash.

You can loosen the four outer hex screws, tighten or loosen the center set screw, and then tighten down the four outer hex screws to make the cross slide handle easier or more difficult to rotate. This is how I lock my cross slide!

One *extremely* important point here is that if you make it too tight the cross slide power feed will not work, much in the same way that a cross slide power feed would not work if the cross slide were locked.

To make the same point again, one day I had my cross slide handle (rotation) set so tightly that I was afraid for several minutes that my cross slide power feed had ceased operating! So don’t go crazy with those 4 screws with the set screw in the middle; easy does it. If you are using these as a cross slide lock, definitely make sure that you loosen them back up before using the cross slide power feed!

If you have a taper attachment, then it may not be aligned properly and the end bearing is too tight. I haled install one of these on the 1640 lathe, it was very heavy and a two man job. If the alignment was not spot on the it would bind. These lathes from the factory should be pretty spot on as t their specs. and tolerances, if the cross slide handle is too tight with the gibs removed then it is either the bearings or the nut. Manual on the taper attachment should be the same as the SB1263. I would speak to PM/QMT and take their direction before going further, the taper attachment is very heavy and its alignment needs to be very accurate. There were some taper dowel pins installed to set the alignment, and could be an issue with the end bearing preload.

Like you, I had PM install the taper attachment, and I didn’t want to mess with their install vis a vid the aforementioned “blocked cross slide lock (set screw)”.

You should experiment with those 4 outer bolts and the inner set screw to get your cross slide handle rotation to the desired stiffness. I like mine pretty tight.

I am sorry that I have not joined in on this discussion until now, but I am working crazy long hours & finishing up a bunch of spindles for the dividing head group project.

I also thought something was binding or out of alignment, yesterday, and took off the cap to see what's under the hood:

In the process I stripped one phillips head screw top and had to hammer it free with a pick: They were really jammed in at PM. I'll be replacing the 5mm 0.8 with star screws, so that next person will be able to open it. There is a bearing there:

I'm keeping my fingers crossed that is not the the problem.

Another member here, @erikmannie who received a 1640TL with a pre-installed taper unit was also having problems with a tight cross slide. I wonder if he resolved his problem.

Thank goodness for this community.

Yikes. I saw others post how they did it. Also, someone last week received a 1640TL and a VFD. I am hoping that he ordered the Yamaha unit from PM. I am hoping to be a copy-cat.Lots of feedback on your cross slide issue but you may need an expert to jump in on this comment. I have a VFD on my 1440TL and I had to fully re wire the lathe before I could get the first spindle turn. I don’t believe you can just pull 3 phase from your VFD and wire into the lathe?? Maybe that is not what you meant above? Again maybe an expert can clarify. You need to wire directly from the VFD to the motor and then set up the correct controls to test the lathe. For me that was pulling all the high voltage wiring out and re wiring control wiring back to the VFD.

Once I get the non-cooperating cross slide (taper unit) issue resolved, VFD is the next project.

- Joined

- Sep 1, 2020

- Messages

- 554

If you have a model to follow sounds good. I have the Hitachi VFD from PM and only know one way to connect it as learned from @mksj. If you are doing something similar then great. Just sounded like you were going to hook it up directly and use it like a Rotary Phase Converter and I am not aware of how that would work? But I am also not an expert. Good luck.Yikes. I saw others post how they did it. Also, someone last week received a 1640TL and a VFD. I am hoping that he ordered the Yamaha unit from PM. I am hoping to be a copy-cat.

Once I get the non-cooperating cross slide (taper unit) issue resolved, VFD is the next project.

- Joined

- Jun 12, 2014

- Messages

- 5,056

I am not sure how many times this is repeated, but the VFD is not a plug and play power source for a machine. The motor output is directly wired to the VFD, no contactor, no switches, etc. If you want plug and play get an RPC. BIIB outlined in his video how he installed his VFD, so why not take a look at that if you want to do a basic install that uses the contactors to switch the low voltage VFD inputs and you also need to change out the brake switch to a dual pole so one side is wired like the factory and the other side issues a free run command. I am not aware of a Yamaha VFD, there is a Yaskawa brand, but PM/QMT only sells the Hitachi WJ200 series. The model most commonly used for a 5 Hp motor would be the WJ200-075LF, which is a 3 phase input unit run in a derated mode for single phase. Yaskawa does make a native single phase input 5Hp VFDGA50UB018ABA which is a bit more complicated than the WJ200 and takes a different set of parameters.

GA50UB018ABA - 5 HP, 17.5 Amps, Heavy Duty, 240 VAC, Single-Phase, IP20/Protected Chassis

Yaskawa - GA500 AC Microdrive - GA50UB001ABA - 1/16 HP, 1.2 Amps, Normal Duty, .17 HP, 0.8 Amps, 240 VAC, Single-Phase, IP20/Protected Chassis

control-concepts.myshopify.com

I just talked to technical support at PM. He said that you are the MAN w/r/t VFD . So, I'll review your postings before I enter that rabbit hole.I am not sure how many times this is repeated, but the VFD is not a plug and play power source for a machine. The motor output is directly wired to the VFD, no contactor, no switches, etc. If you want plug and play get an RPC. BIIB outlined in his video how he installed his VFD, so why not take a look at that if you want to do a basic install that uses the contactors to switch the low voltage VFD inputs and you also need to change out the brake switch to a dual pole so one side is wired like the factory and the other side issues a free run command. I am not aware of a Yamaha VFD, there is a Yaskawa brand, but PM/QMT only sells the Hitachi WJ200 series. The model most commonly used for a 5 Hp motor would be the WJ200-075LF, which is a 3 phase input unit run in a derated mode for single phase. Yaskawa does make a native single phase input 5Hp VFDGA50UB018ABA which is a bit more complicated than the WJ200 and takes a different set of parameters.

GA50UB018ABA - 5 HP, 17.5 Amps, Heavy Duty, 240 VAC, Single-Phase, IP20/Protected Chassis

Yaskawa - GA500 AC Microdrive - GA50UB001ABA - 1/16 HP, 1.2 Amps, Normal Duty, .17 HP, 0.8 Amps, 240 VAC, Single-Phase, IP20/Protected Chassiscontrol-concepts.myshopify.com

I don't know why I started to think the VFD from PM was a xxxxx. It is a HITACHI. A very my-bad.

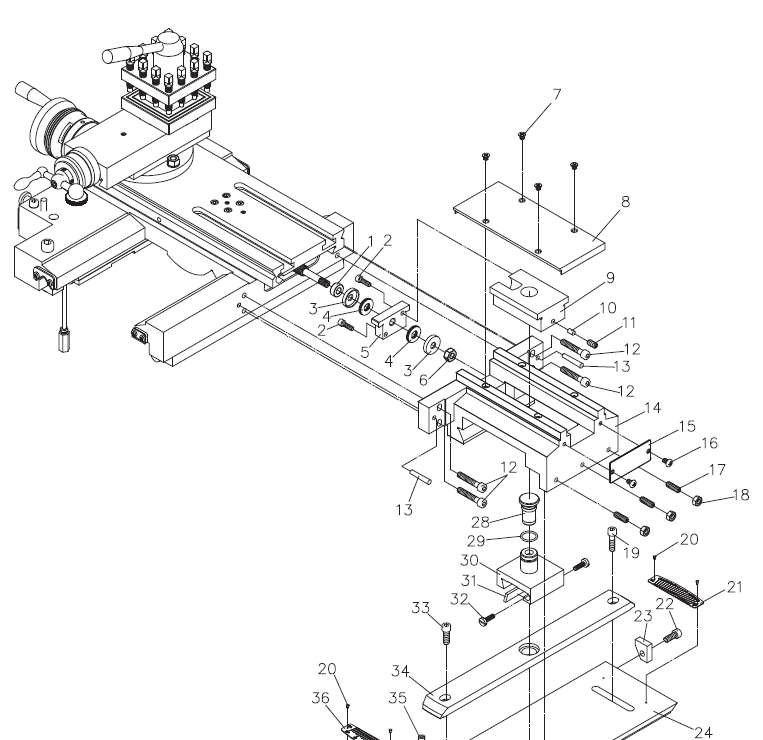

Very good news form PM technical support about the stiff cross slide hand wheel. They know about the problem. They check to make sure that the cross slide does slide at installation time, before shipping. The attachment could have settled, during shipping, causing a binding.

The suggestion is to loosen bolts 12 (four of them) and adjust the attachment upwards. I intend to use a home made gantry to control the adjustment of the up lift. I ask him wouldn't registration pin, 13, prevent the up lift? PM DOES NOT pin the attachment ! (Southbend knew what they were doing, to use the pins.)

After I get this working again, a micro vertical adjustment for the attachment seems in order. If it slipped once, it can slip again. As I work on this, I'll be thinking of where such a thing might fit.

The suggestion is to loosen bolts 12 (four of them) and adjust the attachment upwards. I intend to use a home made gantry to control the adjustment of the up lift. I ask him wouldn't registration pin, 13, prevent the up lift? PM DOES NOT pin the attachment ! (Southbend knew what they were doing, to use the pins.)

After I get this working again, a micro vertical adjustment for the attachment seems in order. If it slipped once, it can slip again. As I work on this, I'll be thinking of where such a thing might fit.

A quick look: It looks like the taper unit is bolted to the back side of the carriage. Unite 14 is bolted with items 12. PM does not use registration pins, item 12.Very good news form PM technical support about the stiff cross slide hand wheel. They know about the problem. They check to make sure that the cross slide does slide at installation time, before shipping. The attachment could have settled, during shipping, causing a binding.

The suggestion is to loosen bolts 12 (four of them) and adjust the attachment upwards. I intend to use a home made gantry to control the adjustment of the up lift. I ask him wouldn't registration pin, 13, prevent the up lift? PM DOES NOT pin the attachment ! (Southbend knew what they were doing, to use the pins.)

View attachment 376242

After I get this working again, a micro vertical adjustment for the attachment seems in order. If it slipped once, it can slip again. As I work on this, I'll be thinking of where such a thing might fit.

The bad news is that on careful observation, item 14 seems to slope down from the back of the carriage. How can that be? I'll have to indicate some machined horizontal surface of item 14.

On a quick look it looks like the taper unit was mounted onto a painted surface. I'll have to check that out tomorrow, but if so, it is not surprising that during shipment, the unit would have crushed the paint and thereby settled in a slope: the axis of the cross slide screw and the unit then would not be colinear and the bearing that is housed in item 14 would not be perpendicular to the axis of the cross slide screw.

I hope mine is the only one that is like this. Others who have the taper unit might see if it was mounted over a painted surface.