Yes. The picture is exactly what I was talking about earlier. It looked like a missing screw to a novice.Glad you got it sorted. Just checked mine and was sending you this picture to confirm there is one in there. 3mm. Just deep. I have it uncovered and it was full of chips and seems fine uncovered. Tape will likely get oily and messy.

Also, I find that Kerosene works better than WD-40 when cleaning a whole machine. Stiff brush to apply, let it sit a bit and hard plastic scraper like for window tinting to scrape off the flats. Repeated brushing for things like the lead screw. I use a cup and sort of reclaim the kerosene until it is to full of gunk then get a fresh bit in the cup. Cleans well and won’t hurt the paint. Good luck.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM-1660TL

- Thread starter erikmannie

- Start date

- Joined

- Sep 1, 2020

- Messages

- 554

The 3 Jaw is noticeably heavier. I would guess 75-80 lbs. I made some cradles from the 4x4’s of the pallet. That makes them easy to slide in and out of the spindle. A cradle is not required, Just make sure you have something across the ways to protect the lathe when moving chucks. I also recommend marking the 4 jaw if not already so you put it on the same every time. Not as critical as a 3 jaw but still seems like a good idea to ensure the cams engage the same every time.

Attachments

Last edited:

Thanks for the pictures. The skid is very cool. I used to be able to lift 100 pounds and not think much of it. But now, I don't have the confidence. Also, its different than lifting weights in a gym where dropping the weight can not be compared to dropping a chuck in the shop.

How do you safely get the chuck onto and off the skid?

Is it ok to mill wood on a metal milling machine? What happens to the saw dust when it absorbs oil?

How do you safely get the chuck onto and off the skid?

Is it ok to mill wood on a metal milling machine? What happens to the saw dust when it absorbs oil?

- Joined

- Sep 1, 2020

- Messages

- 554

On and off the Chuck cradle I just carry it still. But don’t have to hold long to align it so pretty quick lift and out in the open on the ways. The cradle is a nice fit to align the cams so slide it over to get it in place and when you are pulling the Chuck off it slips out of the spindle and right onto the cradle.

Machining wood on any metalwork machine is fine. Just have to clean up the mess. I try to wipe up any protective oil before doing wood to make for easier clean up, and then be sure to oil well after since the wood dust will suck away any remaining oil. Oily wood chips are just oily wood chips. Nothing special about them. If you have ever run a chainsaw you have dealt with oily wood chips.

Machining wood on any metalwork machine is fine. Just have to clean up the mess. I try to wipe up any protective oil before doing wood to make for easier clean up, and then be sure to oil well after since the wood dust will suck away any remaining oil. Oily wood chips are just oily wood chips. Nothing special about them. If you have ever run a chainsaw you have dealt with oily wood chips.

Thanks. Good to know, about wood on metal machines.On and off the Chuck cradle I just carry it still. But don’t have to hold long to align it so pretty quick lift and out in the open on the ways. The cradle is a nice fit to align the cams so slide it over to get it in place and when you are pulling the Chuck off it slips out of the spindle and right onto the cradle.

Machining wood on any metalwork machine is fine. Just have to clean up the mess. I try to wipe up any protective oil before doing wood to make for easier clean up, and then be sure to oil well after since the wood dust will suck away any remaining oil. Oily wood chips are just oily wood chips. Nothing special about them. If you have ever run a chainsaw you have dealt with oily wood chips.

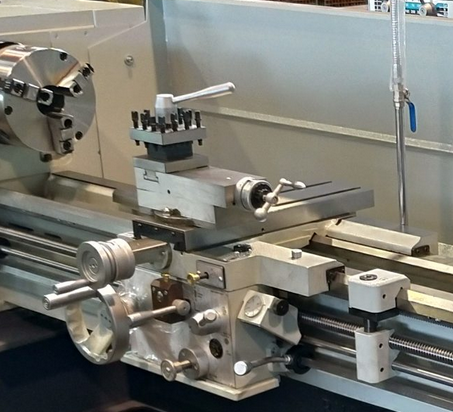

Below the text, there is a portion of a picture from the PM site of a PM-1640TL. It shows the cross slide with a small hole on the right side of the slide. My machine was ordered with a taper attachment and a DRO installed. The DRO installation makes the hole inaccessible.

I am guessing that the small hole on the right side of the cross slide contains a set screw for locking the cross slide. The manual does not show the hole, nor a set screw, if any. If anyone has received a PM-1640TL without a DRO installed, can you please confirm what is there?

Yes, I know, I can call PM and ask. But I already called them on a newbie question this week.

Does the taper unit make the lock unnecessary?

I am guessing that the small hole on the right side of the cross slide contains a set screw for locking the cross slide. The manual does not show the hole, nor a set screw, if any. If anyone has received a PM-1640TL without a DRO installed, can you please confirm what is there?

Yes, I know, I can call PM and ask. But I already called them on a newbie question this week.

Does the taper unit make the lock unnecessary?

- Joined

- Jan 21, 2013

- Messages

- 919

You can move the scale and the read head away using spacers. This will allow you to get at the locking screw. Most people replace that screw with a hex head bolt which allows you to have the scale fit right up behind it while using a flat wrench to lock/unlock.Below the text, there is a portion of a picture from the PM site of a PM-1640TL. It shows the cross slide with a small hole on the right side of the slide. My machine was ordered with a taper attachment and a DRO installed. The DRO installation makes the hole inaccessible.

Yes, I know, I can call PM and ask. But I already called them on a newbie question this week.

Does the taper unit make the lock unnecessary?

We allow 2 newbie questions a week!

It does not make the lock unnecessary, but you wouldn't use it while using the taper attachment.