Hey Tomzo, I wanted to say a sincere THANK YOU for researching and posting this. I also own an MX-120V with the same aggravating "power off everything" behavior when switching spindle directions, and also implemented a Clough42 ELS, so the powering off between cycles of ELS thread cutting was SUPER annoying.

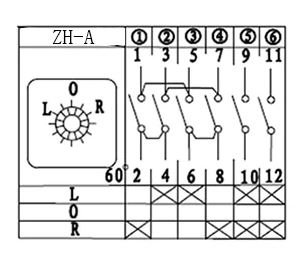

I'd pulled my switch out of my lathe to find its part number and was Google searching for its wiring sheet so that I could disable that power-off "safety" ... when I happened across this thread in the Hobby Machinist, which solved the problem. Simply disconnecting the red and orange wires from posts 9 and 10 and connecting them together in a wire nut keeps the power on through direction changes. (Of course, we now need to be diligent to ensure that the spindle is completely stopped between directon changes, but that's simple enough.)

After finding this thread, I registered on this Hobby Machinist forum just so that I could say THANKS to you. (It took overnight to be approved.) And now that I'm here, it seems like a great resource for other things too, and I'm sure I'll stick around.

I was about to post a link to my own thread in the ELS "Issues" section in Clough42's GitHub, but remembered that the Hobby Machinist acceptance requires that I make at least three appends before linking anything. Anyway, I'm sure you can find my issue #224 thread there. And in it, you'll find a link to a video that I posted to show my ELS setup to introduce the problem. (I also show pics of the before and after switch mod.) I'm sure you must've completed your own MX-210V ELS setup by now, but if not, you might be interested in seeing my implementation. And of course I'd be happy to share the 3D printed designs with you (encoder bracket, ELS display mount, gears) if they'd help.