- Joined

- Nov 24, 2014

- Messages

- 3,575

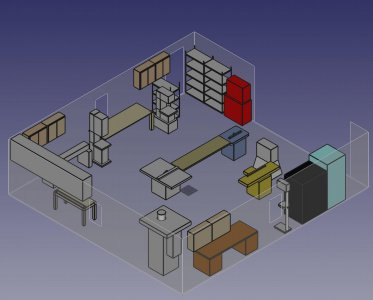

Simple CAD sketch. Imagine the cylinder is a brush, free to spin, moves across the beam with the end truck. Because of friction, the cylinder will spin. Because the cylinder is at an angle, the bristles have some motion that is toward the flange edge. Since it is rotating, debris is much less likely to stick to the brush. Since this beam is about 11' up, I think a fairly soft bristle would be effective in remove the dust likely to find it's way up there, I don't foresee heavy debris, maybe a few chips but even that is unlikely.

View attachment 416394

Figure a bristle tip sticks to the beam for a small distance, over which distance the brush angle induces some deflection toward the beam edge. When the bristle tip releases, that deflection results in the bristle springing back in a direction toward the beam edge.

I familiar with the concept from wheel rakes for hay, but the same principle is used as a conveyor brush

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.www.mcmaster.com

In a crane application it would tend to sweep right in one direction of travel, and left in the other. A slotted mount for one side of the brush axle would allow it to pivot so that it would sweep off the same side regardless of travel direction.

Thanks for the explanation. If you like the angled, unpowered, slotted mount, rotating cylindrical brush concept, I'm 100% OK with your choice. It's your project and I'm sure that what ever you come up with, in the end, will suit your purpose.

I guess I'd have to test the concept to see how it would perform. I'm not hopeful.

I think the wheel rake is a vastly different and specialized apparatus. It doesn't help me understand the efficacy of unpowered cylindrical brushes. I'm also underwhelmed by the conveyor brush example. After all, a conveyor belt recirculates so gravity will remove debris. IMO, regarding "light cleaning", a conveyor brush can have a scrubbing effect on the surface of the belt which may dislodge adhered contamination allowing gravity to finish the cleaning.