-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New shop! (was: Multiple buildings, ...)

- Thread starter rabler

- Start date

- Joined

- Feb 25, 2021

- Messages

- 3,271

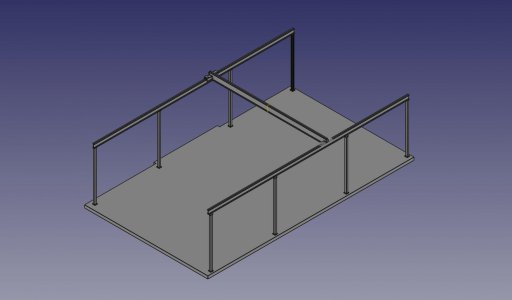

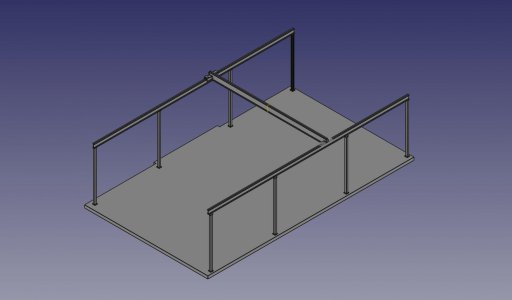

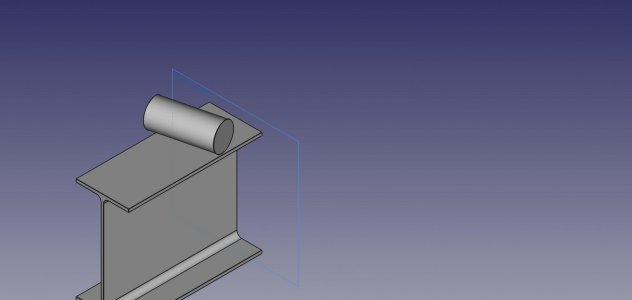

Designing the crane in FreeCad. Initial issue is to get the layout and length for the legs. Then I can fab the legs and drill the anchors. Upper structure will be installed later. This design will get some additional bracing. I'll connect the ends of the side rails together, and put in some diagonal bracing between the legs.

Crane spans 22' for the bridge, and about 38' long side rails. Capacity will be 1 ton. Higher capacity would be more expensive, and more importantly, heavier. I'm going for an unmotorized design.

For the FreeCad users, I did this as multiple components in version .20, and then assembled the components as multiple copy/pasted bodies. There are certainly more elegant ways to do this, including the various assembly workbenches, but I'm all about straightforward brute force, not trying to get any fancier than needed with the CAD tools, especially as fancy things in FreeCad tend to result in total melt downs.

.

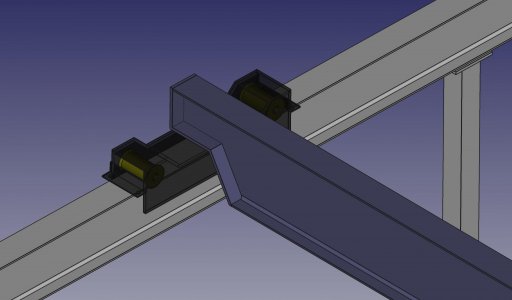

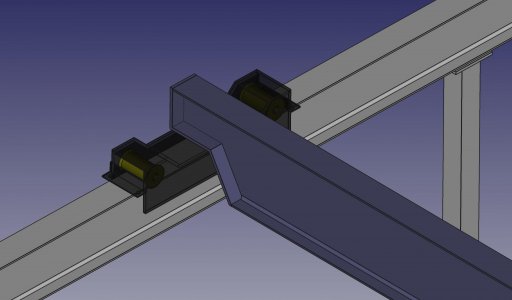

These end trucks are 24" long as shown. Going to redo them to be 36" long. Longer means not quite getting as close to the end walls, but will reduce issues with the bridge beam racking off square. There will be follower wheels to keep them square on the rails, just didn't add those, or the bushings and axle bolts, etc, into the CAD.

Crane spans 22' for the bridge, and about 38' long side rails. Capacity will be 1 ton. Higher capacity would be more expensive, and more importantly, heavier. I'm going for an unmotorized design.

For the FreeCad users, I did this as multiple components in version .20, and then assembled the components as multiple copy/pasted bodies. There are certainly more elegant ways to do this, including the various assembly workbenches, but I'm all about straightforward brute force, not trying to get any fancier than needed with the CAD tools, especially as fancy things in FreeCad tend to result in total melt downs.

.

These end trucks are 24" long as shown. Going to redo them to be 36" long. Longer means not quite getting as close to the end walls, but will reduce issues with the bridge beam racking off square. There will be follower wheels to keep them square on the rails, just didn't add those, or the bushings and axle bolts, etc, into the CAD.

Last edited:

- Joined

- Nov 24, 2014

- Messages

- 3,575

A couple comments on the trucks. I would want the largest diameter wheels that I could package within the other dimensional constraints. Full width (across the beam flange) isn't necessary.

www.mcmaster.com

www.mcmaster.com

You might consider incorporating some kind of strip brush at each end of each truck.

www.mcmaster.com

www.mcmaster.com

That is going to be Soooo nice.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

You might consider incorporating some kind of strip brush at each end of each truck.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

That is going to be Soooo nice.

Last edited:

- Joined

- Nov 24, 2014

- Messages

- 3,575

Thinking about the brushes a little more, I would modify and mount some wire brushes, rather than those wimpy conveyor brushes I linked above.

Lincoln Electric 9 in. Long Wooden Handled Carbon Steel Welding Wire Brush (.8 in. x 4.9 in. Bristle Area 4 x 16 Row) KH585

Lincoln Electric Wooden Shoe Handle Carbon Steel Brush is a heavy-duty brush for cleaning metal and removing slag. The brush has 4 rows of bristles in an ergonomic wooden handle. The brush measures 10-1/4

www.homedepot.com

- Joined

- Feb 25, 2021

- Messages

- 3,271

Yeah, larger wheels would provide smoother rolling. I had already been pondering brush options. The best option would be something mounted at a slight angle, with a rotary brush action. Something a little stiffer, but like:A couple comments on the trucks. I would want the largest diameter wheels that I could package within the other dimensional constraints. Full width (across the beam flange) isn't necessary.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.www.mcmaster.com

You might consider incorporating some kind of strip brush at each end of each truck.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.www.mcmaster.com

That is going to be Soooo nice.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Last edited:

- Joined

- Feb 25, 2021

- Messages

- 3,271

Here's a better option, use two of these in a V

www.eastwood.com

www.eastwood.com

Eastwood Cylindrical Wire Brush - 5 pack

Works with your drill to scrape away rust, paint and other coatings

- Joined

- Nov 24, 2014

- Messages

- 3,575

Here's a better option, use two of these in a V

Eastwood Cylindrical Wire Brush - 5 pack

Works with your drill to scrape away rust, paint and other coatingswww.eastwood.com

Are you thinking of powering cylindrical brushes? Some kind of friction drive off the support wheels would be an interesting project.

Cutting the head off of some hardware store, wooden handled wire brushes would be very simple, inexpensive and effective. They could be mounted on a leaf spring arrangement.

Even using pieces of a squeegee blade would last decades.

- Joined

- Feb 25, 2021

- Messages

- 3,271

Unpowered. Ever seen a hay wheel rake? Same principal. Friction over the surface of the beam spins the brush cylinder. Mounting the cylinder at an angle to the direction of travel results in a sweeping action that is at an angle. Just need a free spinning cylindrical brush.Are you thinking of powering cylindrical brushes? Some kind of friction drive off the support wheels would be an interesting project.

Cutting the head off of some hardware store, wooden handled wire brushes would be very simple, inexpensive and effective. They could be mounted on a leaf spring arrangement.

Even using pieces of a squeegee blade would last decades.

- Joined

- Nov 24, 2014

- Messages

- 3,575

I'm not able to visualize (imagine?) how you would configure those cylindrical brushes (unpowered) to sweep debris in the same direction of travel as the trolley and off the edge of the beam flange. I'm looking forward to the education.

- Joined

- Feb 25, 2021

- Messages

- 3,271

Simple CAD sketch. Imagine the cylinder is a brush, free to spin, moves across the beam with the end truck. Because of friction, the cylinder will spin. Because the cylinder is at an angle, the bristles have some motion that is toward the flange edge. Since it is rotating, debris is much less likely to stick to the brush. Since this beam is about 11' up, I think a fairly soft bristle would be effective in remove the dust likely to find it's way up there, I don't foresee heavy debris, maybe a few chips but even that is unlikely.I'm not able to visualize (imagine?) how you would configure those cylindrical brushes (unpowered) to sweep debris in the same direction of travel as the trolley and off the edge of the beam flange. I'm looking forward to the education.

Figure a bristle tip sticks to the beam for a small distance, over which distance the brush angle induces some deflection toward the beam edge. When the bristle tip releases, that deflection results in the bristle springing back in a direction toward the beam edge.

I familiar with the concept from wheel rakes for hay, but the same principle is used as a conveyor brush

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

In a crane application it would tend to sweep right in one direction of travel, and left in the other. A slotted mount for one side of the brush axle would allow it to pivot so that it would sweep off the same side regardless of travel direction.

Last edited: