Love the progress updates.

Yep, fixed that right/left. Dated a gal in college that couldn't keep right from left straight. Left was "thorn hand" when giving her directions. She had a scar from a thorn. Guess this is payback somehow?

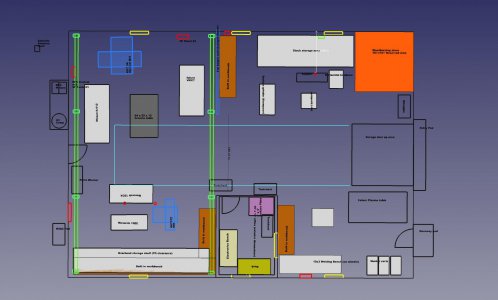

Other steps are really to get the crane legs bolted to the floor, then build the workbenches. I'll also need to wire the in-floor outlets, conduit is there back to the main breaker box but no wiring yet. Then move the smaller machines in and re-organize all of the fixturing, tools, and such. I think the organization will take the longest of all of that. Getting the crane legs bolted in will take some care in placement to keep them lined up. Will wait on the overhead steel for another month, just a budgetary issue. Steel is pricey.

That corner is the one with the poorest lighting right now. If you notice the light strip isn't even fully assembled. I'm using 8' LED strips. I'll add two more strips over that area. If I recall correctly I have 10 currently installed. They can daisy chain up to 3 per plug, I have 6 receptacles (12 outlets total) in the ceiling, all on one 15 amp circuit which is the limiting factor. It's quite a bit of light, don't know the total lumens offhand (it's probably

in one of the previous posts in the thread). Also I eventually plan on building a shelf along the wall just above the window in the first picture. 3 or 4 LVL joists at 23' long, to make a 4' deep shelf, with 7' clearance underneath (the top of the window is at 7'.) If you look at that wall there are two outlets just below window top height on either side of the window, and a switch next to the window. That's to hang more work lights under that shelf over the bench if needed.

Yep, I'm ready to start using the shop rather than working on it as a project. I've been doing a bit of work on my belt sander just to get my hobby fix, but it is a little annoying as things are split right now between the two buildings, ready to get all the machinng stuff in one place. I also have a long list of machine rehabs that I want to get back to working on. Obviously the 10EE is in need of some TLC. My Monarch CK really needs turcite on the carriage. The 612 needs the cross-slide scraped and the oiler mechanism in there fixed. And two surface grinders that I haven't powered up yet, much less determined what sort of care and feeding they will need.