-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My First Real Drill Press - 1940's Walker Turner 15" Bench DP

- Thread starter wachuko

- Start date

- Joined

- Sep 28, 2013

- Messages

- 4,403

@mattthemuppet2 Very nice!! Thank you for sharing. So many ideas just from those two photos!

You converted to variable speed. Nice. And I can see where you installed the pickup and magnet for the RPM display... Sweet.

Digital caliper on the quill. Cool.

And I see you have the additional pulley for speed reduction.

What are the pulleys in the column for? Lowering and raising the table?

I am finding that the accessories are difficult to find... and the ones I have found, are just ridiculous expensive... 100.00 for a switch housing, 300-450 for the belt cover... 300.00 for that additional pulley setup.

Love that gooseneck lamp... I have a lamp, not on a gooseneck, and it is also missing the lamp shade on mine... need to search for one.

yep, DC treadmill motor, best thing ever on a drill press IMO. I can drill, chamfer and tap without having to change the belt position.

The low speed pulley set up is fairly rare and as you've found, really expensive. For yours I'd invest in a 1/2hp 3 phase motor and VFD instead

The pulleys on the column are for a table counterweight. You can just see the dog food cans attached to the wires on the left. Each is ~2/3 full of lead poured in, plus the odd random wheel weight stuffed in top whenever I find one. Makes a bit difference raising the table with that XY vise on it.

The lamp is what was on it when I found the DP in the "throw out pile" outside the uni machine shop. The socket was broken, so I made an alu insert with an LED.

- Joined

- Aug 6, 2015

- Messages

- 4,298

yep, DC treadmill motor, best thing ever on a drill press IMO. I can drill, chamfer and tap without having to change the belt position.

The low speed pulley set up is fairly rare and as you've found, really expensive. For yours I'd invest in a 1/2hp 3 phase motor and VFD instead

The pulleys on the column are for a table counterweight. You can just see the dog food cans attached to the wires on the left. Each is ~2/3 full of lead poured in, plus the odd random wheel weight stuffed in top whenever I find one. Makes a bit difference raising the table with that XY vise on it.

The lamp is what was on it when I found the DP in the "throw out pile" outside the uni machine shop. The socket was broken, so I made an alu insert with an LED.

For counterweight! Ahh... Never would have thought of that.

On the VFD, I will hold off on any modifications for now... I just can't add one more projects to the list

I did find a gooseneck lamp on Amazon that I can adapt to the DP... I will paint it and that will be it.

Stopped by loves and got a different LED bulb in preparation for the new lamp. Could not resist, so painted it from white to that gray you see in the photo... silly since it will be inside the lamp, but hey... lol. Looking at the photo, I probably could have left it just like that...

- Joined

- Nov 14, 2016

- Messages

- 3,334

Missing the original switch... And the belt cover. Owner told me that he does not recall ever having a belt cover. Looking at the catalog from 1940, not clear if that was an option or not...

Guards were optional items on many old machines. They were available for schools and such that wanted them, but not sold with machines for buyers who would just pull them off and toss them in a corner. Think of the time saved by workers not having to remove a guard to change speeds. Finding the guards for old machines can be hard because there were often far fewer sold than the number of machines made.

OSHA didn't come into existence until 1970.

Neat drill press.

- Joined

- Aug 6, 2015

- Messages

- 4,298

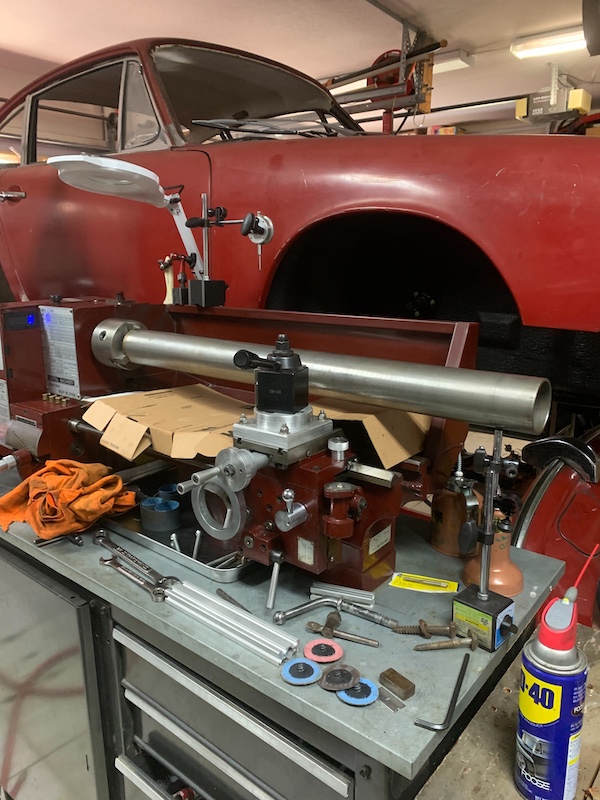

Took it apart to better clean the column... used the lathe to turn the column while I clean it... Got much better results than when trying to clean it in place...

Looking under the base I can see the original color...

And just dropping this in degreaser, got it back to its original color... There seems to be a shortage of spray paint... could not find Rust Oleum Sage Green anywhere... Apparently that is a good match to the factory color. Wanted some to do the top spindle cover that lost all of its paint...

Anyway, got it all back assembled...

Gooseneck lamp also arrived... changed the color from white to a gray. I installed it where the 3rd pulley mounts...

Covered the cable with some abrasive and flame retardant sleeve...

Done!

Looking under the base I can see the original color...

And just dropping this in degreaser, got it back to its original color... There seems to be a shortage of spray paint... could not find Rust Oleum Sage Green anywhere... Apparently that is a good match to the factory color. Wanted some to do the top spindle cover that lost all of its paint...

Anyway, got it all back assembled...

Gooseneck lamp also arrived... changed the color from white to a gray. I installed it where the 3rd pulley mounts...

Covered the cable with some abrasive and flame retardant sleeve...

Done!

- Joined

- Jan 2, 2014

- Messages

- 9,542

Wait What??!?!??!

Did you actually power on the lathe with the entire column in the four-jaw chuck with no support? (tail-stock centre or steady rest)

if so ..... you are still a live, right?

I see so many ways that that could go so bad so quickly!!!

Perhaps you only used sandpaper/scotchbrite by hand on it that still looks like a huge risk to me!!!!!

If you actually touched with a lathe tool than you are very lucky.

Please be safe!

-brino

Did you actually power on the lathe with the entire column in the four-jaw chuck with no support? (tail-stock centre or steady rest)

if so ..... you are still a live, right?

I see so many ways that that could go so bad so quickly!!!

Perhaps you only used sandpaper/scotchbrite by hand on it that still looks like a huge risk to me!!!!!

If you actually touched with a lathe tool than you are very lucky.

Please be safe!

-brino

- Joined

- Aug 6, 2015

- Messages

- 4,298

Wait What??!?!??!

Did you actually power on the lathe with the entire column in the four-jaw chuck with no support? (tail-stock centre or steady rest)

if so ..... you are still a live, right?

I see so many ways that that could go so bad so quickly!!!

Perhaps you only used sandpaper/scotchbrite by hand on it that still looks like a huge risk to me!!!!!

If you actually touched with a lathe tool than you are very lucky.

Please be safe!

-brino

I made a support for the end, yes. Switched the lathe to its lowest speed as well.

I used the 3-jaw chuck.

I was cleaning it with scotch-brite and sandpaper... all by hand.

Not scary at all... No pets or children were harmed during this task

Last edited:

- Joined

- Dec 18, 2019

- Messages

- 7,685

This is cleaning up great! Very nice.A few more photos I forgot to add... Also removed the lock pins for the spindle and column...

View attachment 381524

View attachment 381525

View attachment 381526

After degreasing and cleaning...

View attachment 381530

Nice and clean. Lubed them as well...

View attachment 381527

View attachment 381528

View attachment 381529

Similar threads

- Replies

- 4

- Views

- 447

- Replies

- 3

- Views

- 232

- Replies

- 12

- Views

- 691