- Joined

- Aug 6, 2015

- Messages

- 4,302

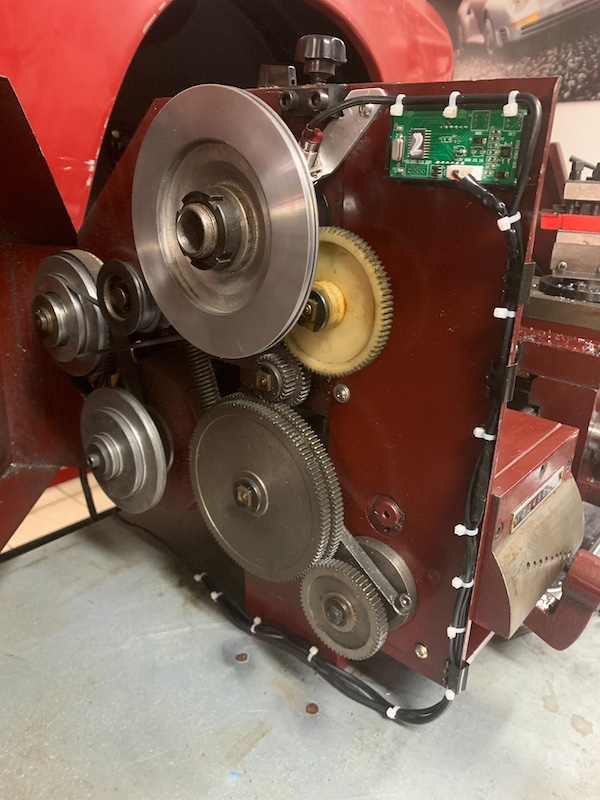

Well... I could not leave things alone... Saw a few folks installing RPM displays on these lathes... so I had to do the same.

Made a cutout on the side cover. Inserted the display there.

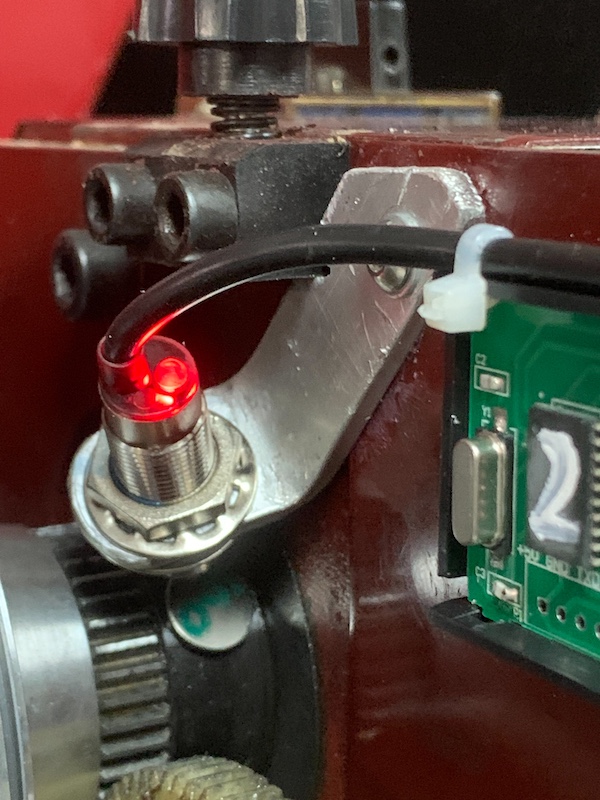

Made a small bracket out of aluminum for the hall sensor. Secured it with a longer bolt on the factory location for one of the bolts that holds the cover. Blue Loctite on everything...

JB weld for the magnet on the spindle...

Had an old 12 volt power supply from an ethernet switch that I had thrown away. Perfect!

I still need to install some wire clamps to permanently secure the wiring. Right now I just used some small binder clips (and removed the handles)... I also need to make a cover for the exposed electronics...

Made a cutout on the side cover. Inserted the display there.

Made a small bracket out of aluminum for the hall sensor. Secured it with a longer bolt on the factory location for one of the bolts that holds the cover. Blue Loctite on everything...

JB weld for the magnet on the spindle...

Had an old 12 volt power supply from an ethernet switch that I had thrown away. Perfect!

I still need to install some wire clamps to permanently secure the wiring. Right now I just used some small binder clips (and removed the handles)... I also need to make a cover for the exposed electronics...

Last edited: