Thanks for the compliment

@woodchucker! As I was just trying I didn’t bother trying to figure out the diameter to pitch. I must of got lucky enough. Is there any recommendations for feed speeds? I’m thinking that the slower you go the more re-forming/cutting that’s happening?

Also I set the tool square to the work. When feeding you could see it flex away from the headstock. Does everyone set it that way or should I be competing for that but rotating it a little bit towards the headstock?

For a scissor type it should be 90 to the stock (MOSTLY), that doesn't mean you can't try to get special effects by skewing it. Everything you do to learn what happens when you do adds to your knowledge, and in this case saying never is just not a good idea. Everything has to be considered.

So 90 is the goal.. but learn what happens when you turn it off 90. Yea, you'll go through stock, but you may learn something. If your knurl is ever giving you problems, maybe your testing will show you something that helps you troubleshoot.

Hints while knurling:

Don't use a brush, most of the time it will get sucked in and cause issues.

Use an oiler or squirt bottle.

Go slow, you are doing a lot of form cutting, and it's tough on small lathes.

Keep flooding it. I've never heard of too much cutting fluid.

Try too much pressure, you will see why, and need to recognize it when you have done it.

I looked up the thread that Will

@darkzero did on knurling. Take a look. These were pretty in Titanium.:

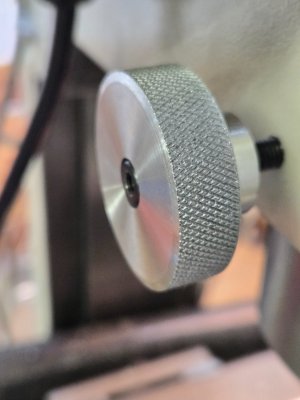

I think my little micro lathe just doesn't have the strength to knurl. The motor stops on pressure and even the tool cross slide moved a bit when I hunkered down. The pic shows about the best I can get.

www.hobby-machinist.com