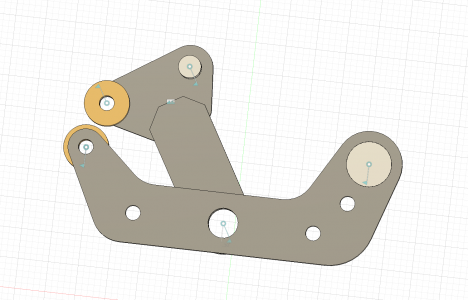

My gut feel if I understand the assembly is that this 'T' joint (orange sketch) is going to be a weak spot because its a relatively small surface area and all the shear force of the tension screw (which is considerable) will be concentrated here. How were you contemplating joining the components?

One idea if you wanted it to keep it 'components' focused vs. entirely milled from solid stock or brazed or something, is to extend the outer sandwich segments a bit (green sketch). That will give you more contact area &/or allow for pins or cross bolts or something. You will have to prove out the scissor action based on diameter range, probably cant go quite as close to the center action as I've sketched.

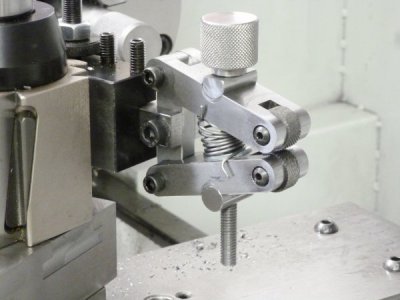

The scissor knurlers I've seen are made from pretty tough stuff. Part of the reason why clones or pseudo-knockoffs give so-so knurling results is they lack rigidity & flex under load, even when good knurl wheels have been swapped in. This can be from combinations of arms, axles, mating surfaces... Anyways my advice is err on the side of more meat = more stiffness & good sliding fits on everything that moves.