I was referring to the axles for the knurling wheels

When I first read that I thought you were talking about the knurl wheel axle. Then I though "no can't be"

I'll try to do this in one picture.

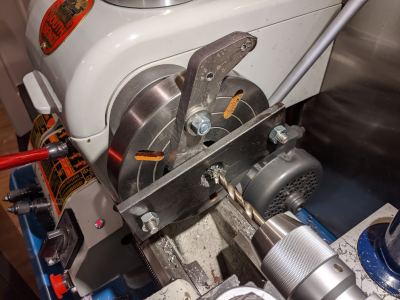

Pinch knurler at the top. Great idea built by someone in the usa originally as I understand it. Then farmed out to china and built there. Then I buy it

. Multiple problems we won't get into but the point is the axle. It's hard but you can see the wear.

Next ....we'll go clockwise... 1" boring bar. I built lots of boring bars in the past and sold some on ebay. Anyway this one is 1" and is set up to do internal knurling on one end. The axle for the wheel is hardened o-1 steel. These axles didn't fair much better than the one in the china pinch tool. And became hard to remove once worn. (pictured one is new). Hard to apply much pressure on a tool like that it has lots of leverage on your tool post so I don't think I was just heavy handed and causing my own problems.

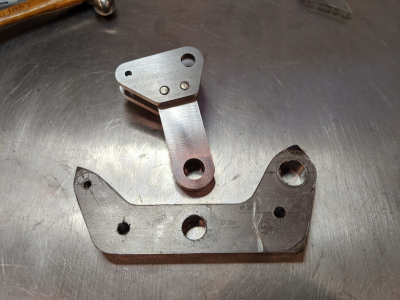

Next is a homemade pinch knurler I made. I used hss axles and "tried" to retain them with the little set screw running parallel to the axle. Arms are D2 steel that was already hard so I had trouble drilling and taping 4-40 so there are some broken bits and broken taps in some of those holes. Top arm has a screw on each side retaining the axle, but the bottom arm has nothing retaining the axle and it has never mover when knurling. It will fall out on the floor if turned sideways so gotta watch that. It's axle and wheel are laying there no wear on the axle. It's been used plenty the small tap holder is an example.

Last knurler is 1/2 of my cnc lathe knurling set up. Other one is mirror image. My lathe is twin turret so I use those as pinch knurlers bringing the turrets together to knurl. I built those they also have hss axles retained by the 4-40 allen screw. There is a groove ground in the hss that the screw enters to keep it in. The screw does not lock it down the axle free floats a small amount.

That pair has run hundreds of those bolt knobs pictured below it. and probably 50 of those handles above it. Black handle is 4130 and has been hardened, shiny handle is W-1 and is not yet hardened.

I actually did a thread bragging that I had the biggest pinch knurler. Lol and posted a u-tube link to a video of the cnc lathe knurling one of those knobs. But that was just before a system crash of this site and that thread was lost.

Whew that's awfully long winded just to say that I think the axles need to be solid hss.

. Multiple problems we won't get into but the point is the axle. It's hard but you can see the wear.

. Multiple problems we won't get into but the point is the axle. It's hard but you can see the wear.