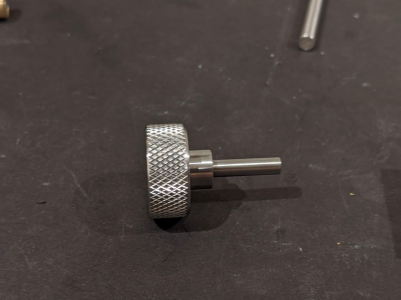

The pin just needs to stay in place. How you do that is up to you but the simpler, the better. A set screw would be simplest. I chose Lautard's method because I didn't have enough real estate for a set screw. Mine accomplishes the same thing as a set screw, just more hassle to make.

The concern with a set screw is the accuracy of the pin hole, which is why I asked if you reamed it carefully. If the pin moves around a lot then that set screw might not hold it. The only way to know is to try it and see, and if it was me I would try the set screw and see if it suffices. If it does then you have the option of using carbide pins and that is a very good thing.