- Joined

- Mar 26, 2018

- Messages

- 8,759

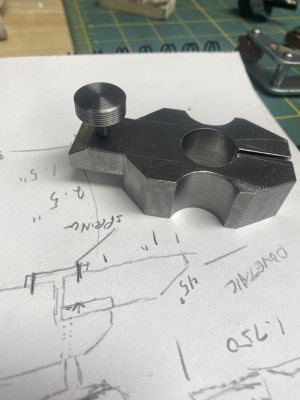

I tried my small fly utter at first then decided to go with the boring head.Too late for the side cuts....

A) Hole saws don't appreciate unguided scallop cuts; this isn't a tube notcher.

B) I don't subject boring heads to such interrupted cuts.

C) Instead, a flycutter does far better. Set the shank in a V block.

Touch off shank with height gauge, subtract one half for centerline.

Add desired radius to centerline.

Raise height gauge to that and set tool tip.

Mount cutter and rough out until depth is reached with a finish pass.

Remainder of project:

I wouldn't radius the front for accuracy, just clearance. Locate exact center of indicator post, bore for a close fitting 1/2" or 5/8" bearing ball, set just deeper than half diameter and stake 3 points- that's the correct contact of a squareness gauge. It's a good plan drilling through for a pin punch to allow replacing the ball.

I’m sure a flycutter would have worked, I just had the wrong grind. I got it done in the end.