-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Got My First Lathe... Logan 1875 - With Restoration.

- Thread starter Mr Mike

- Start date

-

- Tags

- logan 1875

- Joined

- Jul 30, 2017

- Messages

- 635

I assume you are able to buy a new rear take-up nut? Or have someone make you one? You are really diving in deep on this and I enjoy watching.

Hello Larry.. If I cant find or buy one, I'll make one by turning a regular nut down and facing it. Someone over tightened that nut long ago, and I didn't want to risk any damage to the spindle so cutting it off seemed the logical choice. I would never be so brazen to cut off any part that was not replaceable, I would stop and ask for help on the forum or take it to a machinist.

Thanks for looking.. Mike

Last edited:

- Joined

- Oct 18, 2016

- Messages

- 2,872

- Joined

- Jul 30, 2017

- Messages

- 635

Mike, if you replace the nut with another Logan part, you'll need a tool to tighten it. If that's the same size nut as on my Model 200 (1.5" dia.),

you can use a Metric (DIN 1810). 40-42 mm pin spanner. Fits perfectly. I bought mine online from J.W. Winco Inc.

Hi Nogoingback.. Thanks for the suggestion my good man.

I have a very similar tool that I tried first but couldn't budge it....

I'm guessing someone used the take-up nut to tighten the chuck to the lathe which also

caused the bearings to bind, then after sitting for 20+ yrs the thin lubricant film turned to glue.

Even a foot long channel lock would't budge it held in a vise using 9/16 All-Thread through

the spindle held with washers and nuts fully tightened..

I tried the most common methods to loosen the nut.. they all failed, And I didn't want to chance damaging the spindle by using too much force or use of a blunt instruments.. After I removed the spindle, I figured out that I could have used my press from the spindle front to back the take-up nut and spacer off the rear bearing.

Live and learn. I've always said, Experience is what you get just after you need it.

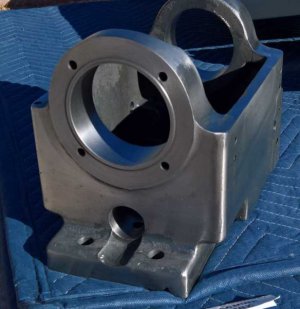

On the plus side, Electrolysis of the headstock has been completed

This is strait out of the electrolysis bath, I used Mikeys method for stopping flash rust a 50/50

mix of Phosphoric acid, Remove most the water then spray it on and let it sit, rinse and dry.

The headstock was in the tank for 16 hrs @ 2 amps. there are a few patches of paint left

in the interior that will just act as additional protection after being painted.

Cleaned up with a very fine Scotch Bright pad.

Last edited:

- Joined

- Oct 18, 2016

- Messages

- 2,872

Well after all that, I can see why you cut the nut off. Certainly easier than replacing than the spindle. One thing I don't understand is why it

caused the bearings to bind since Logans use ball bearings that aren't adjustable. The tension on that nut shouldn't have anything to

do with bearing preload. On mine the rear (small) bearing "floats" in the headstock with no lateral pressure on the outer race. When you

re-assemble you might want to look for some other cause for binding. What shape are your bearings in?

Looks as though you're doing your usual excellent job on the headstock casting.

caused the bearings to bind since Logans use ball bearings that aren't adjustable. The tension on that nut shouldn't have anything to

do with bearing preload. On mine the rear (small) bearing "floats" in the headstock with no lateral pressure on the outer race. When you

re-assemble you might want to look for some other cause for binding. What shape are your bearings in?

Looks as though you're doing your usual excellent job on the headstock casting.

Last edited:

- Joined

- Jul 30, 2017

- Messages

- 635

I assume you are able to buy a new rear take-up nut? Or have someone make you one? You are really diving in deep on this and I enjoy watching.

Hi Larry, Yes I can replace the take-up nut with an new original, Not all but many original parts are still available from Logan Actuator.

If you happen to have a Logan 1875 and need precise photos of the disassembly of any component, I have hundreds of them that don't make it to the forum and if you need to see a particular item I bet I have it... Thanks for looking, Mike.

Last edited:

- Joined

- Jul 30, 2017

- Messages

- 635

Mike, if you replace the nut with another Logan part, you'll need a tool to tighten it. If that's the same size nut as on my Model 200 (1.5" dia.),

you can use a Metric (DIN 1810). 40-42 mm pin spanner. Fits perfectly. I bought mine online from J.W. Winco Inc.

Looks like this:

View attachment 247602

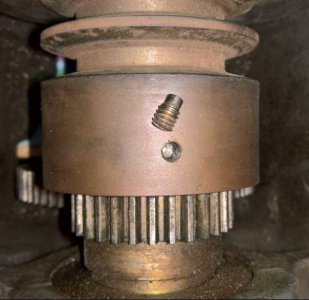

Hi Nogoingback, It looks like you just added a new belt to your lathe, I love how nice your gears look - amazing how much work it is just to change a belt.

- Joined

- Oct 18, 2016

- Messages

- 2,872

The new belt was part of a bigger project to "overhaul" my lathe after I bought it. Everything came apart, repairs were made, parts replaced

(including headstock bearings) etc., etc. Of course, what I didn't do was paint it. It's a WW II era lathe with what I assume is US Army spec.

color that was applied over the Logan gray. It wasn't rusty and the paint, though showing honest wear isn't bad. And I'm lazy. And yes,

the gears were great: all perfect and only missing one change gear.

You're right, changing belts is a pain. The belt I bought came from Logan, though if I were to do it again I'd consider a cam belt from

the auto parts store: I've had some problems with slipping with the belt that I have.

(including headstock bearings) etc., etc. Of course, what I didn't do was paint it. It's a WW II era lathe with what I assume is US Army spec.

color that was applied over the Logan gray. It wasn't rusty and the paint, though showing honest wear isn't bad. And I'm lazy. And yes,

the gears were great: all perfect and only missing one change gear.

You're right, changing belts is a pain. The belt I bought came from Logan, though if I were to do it again I'd consider a cam belt from

the auto parts store: I've had some problems with slipping with the belt that I have.

- Joined

- Jul 30, 2017

- Messages

- 635

So I started work on all kinds of stuff over the weekend and also finished painting the interior of the cabinets...

Talk about no fun at all, I don't suppose it would make much difference at this point if I called Logan and complained about not being able to remove the center cabinet shelf.. Ya know for the people that restore it 30 years later..)

There is only around 8" inches between the upper and middle shelf making it really hard to get a can in there.. I also see that it was hard for them as well via the paint runs I found in that area while prepping it.

Talk about no fun at all, I don't suppose it would make much difference at this point if I called Logan and complained about not being able to remove the center cabinet shelf.. Ya know for the people that restore it 30 years later..)

There is only around 8" inches between the upper and middle shelf making it really hard to get a can in there.. I also see that it was hard for them as well via the paint runs I found in that area while prepping it.

- Joined

- Jul 30, 2017

- Messages

- 635

Last edited: