- Joined

- Mar 26, 2018

- Messages

- 2,725

Well I have been doing a lot of redesign on my 4th axis since I am now getting serious about building it.

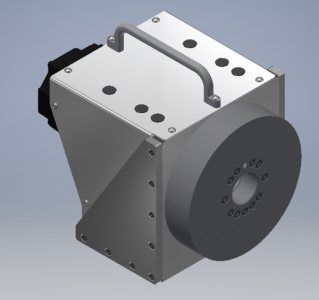

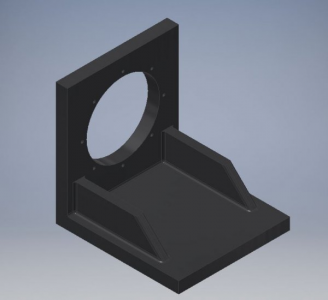

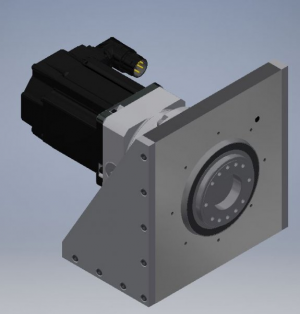

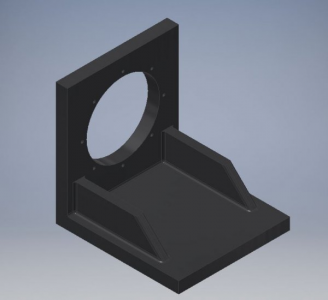

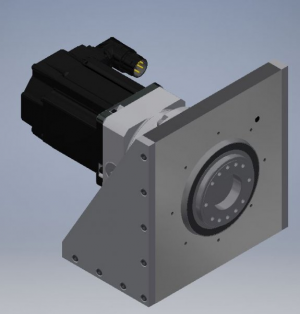

Here was the mock-up proof of concept design:

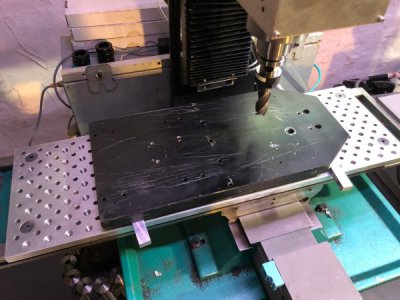

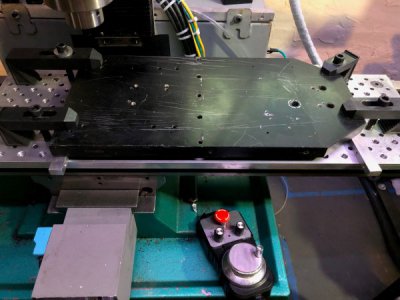

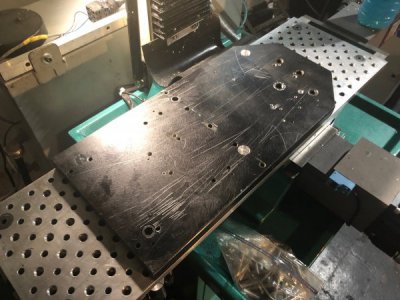

Notice almost everything is missing including mounting holes and the homing proximity sensor. Here is the cast iron angle plate as machined.

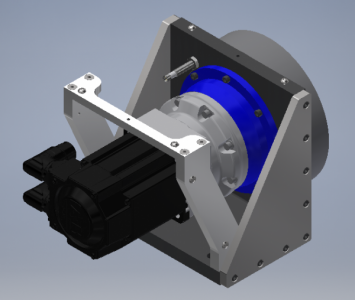

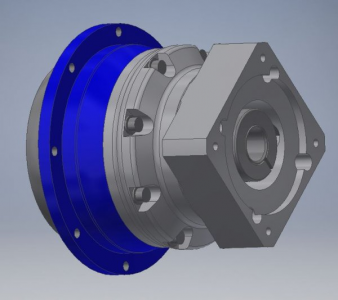

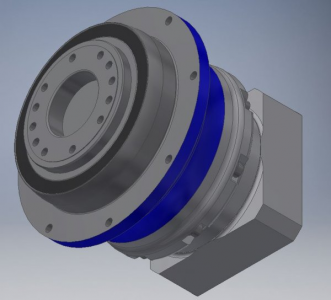

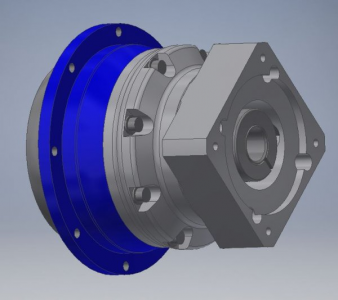

Here is the Alpha Wittenstein TP+ 1:31 gearbox I am using

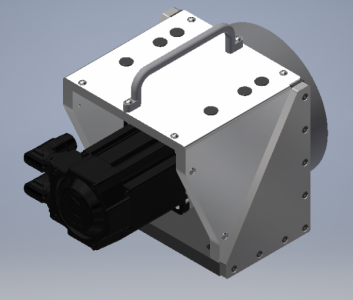

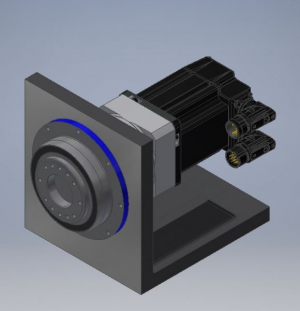

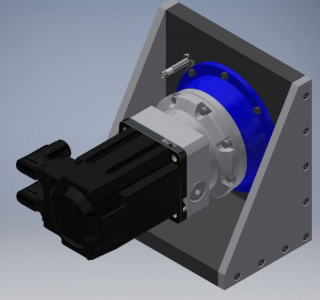

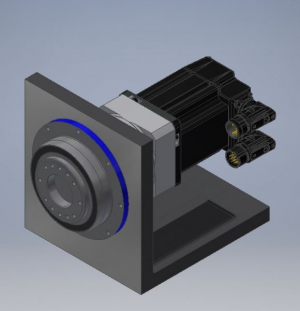

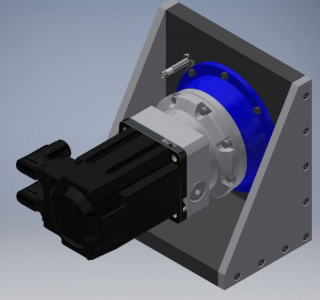

Here is a picture from partway through the design. Notably there have been side plates added, the gearbox is now mounted from the rear, and the Balluff inductive proximity sensor has been added.

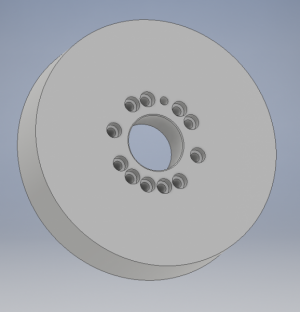

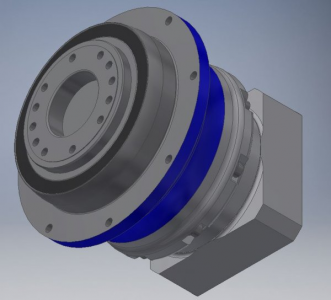

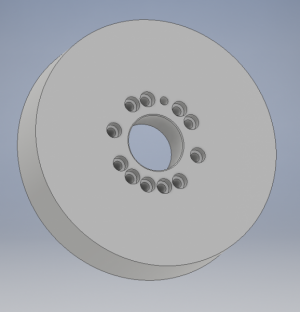

Next I designed a cast iron faceplate for this unit which will allow mounting of various fixtures including lathe chucks and tombstones.

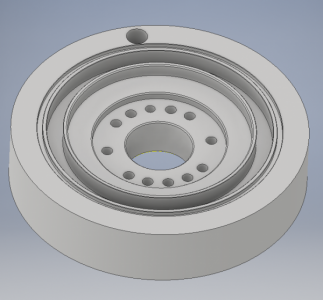

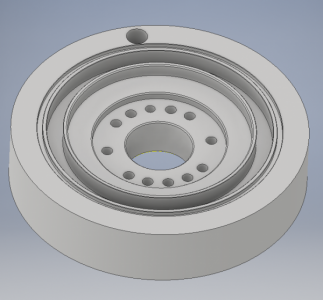

The rear of this faceplate is quite complicated due to grooves for sealing rings. As I have continued with the design, I am pretty sure I will remove the seals and rely on the seal integral to the gearbox.

Here is a mock-up of the design on my G0704. Note that the model of the rest of the machine doesn't include the most up to date spindle design or limit switch mounting.

After this point I shortened the assembly by 1/2" and updated the mounting holes. I intend to further update it to include a carry handle on top and provisions for a sheet metal cover. I also need to model mounting features onto the faceplate.

I'm currently worried about weight. This unit as it is modeled comes in just shy of 60 pounds. This is a lot of weight to be hanging off of the end of such a small mill.

Open to design ideas!

Mike

Here was the mock-up proof of concept design:

Notice almost everything is missing including mounting holes and the homing proximity sensor. Here is the cast iron angle plate as machined.

Here is the Alpha Wittenstein TP+ 1:31 gearbox I am using

Here is a picture from partway through the design. Notably there have been side plates added, the gearbox is now mounted from the rear, and the Balluff inductive proximity sensor has been added.

Next I designed a cast iron faceplate for this unit which will allow mounting of various fixtures including lathe chucks and tombstones.

The rear of this faceplate is quite complicated due to grooves for sealing rings. As I have continued with the design, I am pretty sure I will remove the seals and rely on the seal integral to the gearbox.

Here is a mock-up of the design on my G0704. Note that the model of the rest of the machine doesn't include the most up to date spindle design or limit switch mounting.

After this point I shortened the assembly by 1/2" and updated the mounting holes. I intend to further update it to include a carry handle on top and provisions for a sheet metal cover. I also need to model mounting features onto the faceplate.

I'm currently worried about weight. This unit as it is modeled comes in just shy of 60 pounds. This is a lot of weight to be hanging off of the end of such a small mill.

Open to design ideas!

Mike