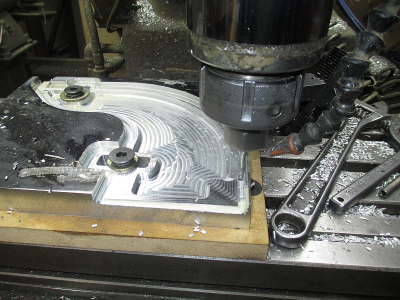

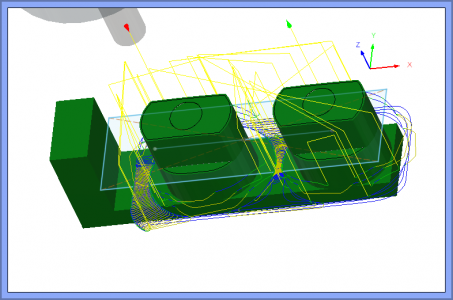

Another interesting work holding exercise. In this case two special T-nuts. This is one of the rare instances that leaving the part attached to the base material makes sense. I have only actually done this two other times. In one case it was another set of T-nuts, and the other ''U'' shaped part that did not lend itself to other holding techniques.[...]

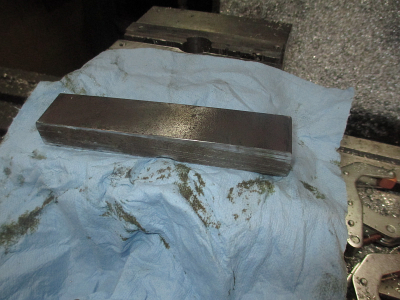

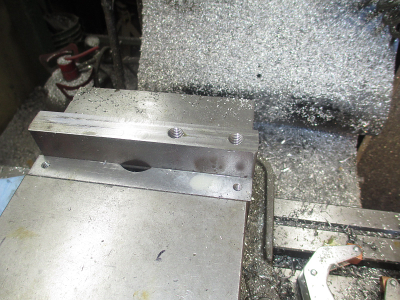

So start out with a 1 1/4 x 3/4 x 6 chunk off of the steel

scrap excess inventory shelf. Not sure what it is, A36 or 4140? Some kind of hot rolled.[...]

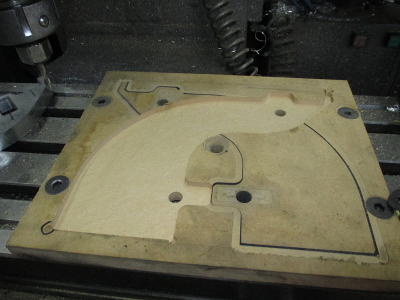

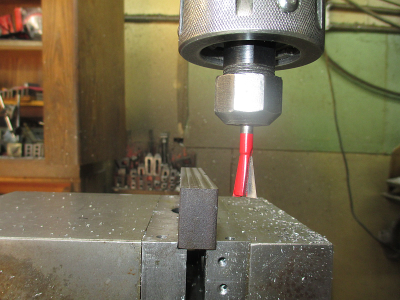

Face it off, with a 3/8 end mill, no face mill or flycutter required. Then cut a dovetail to match the dovetail in the vice jaws. WAIT! WHAT? Dovetail in the vice jaws?

[...]

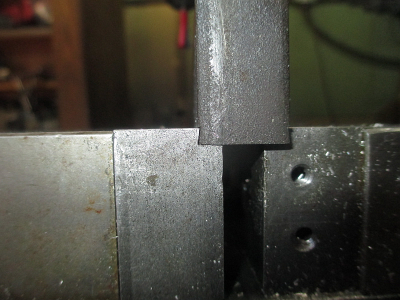

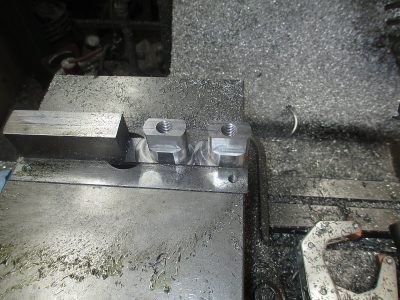

Yup, dovetail in the vice jaws. These are steel soft jaws. While I own a set of hard jaws, they sit on the shelf and gather dust, I don't use them. I make steel and aluminum soft jaws as needed, I have even made MDF jaws for special holding needs. I have been using this particular set of soft jaws for at least 4 years. Much more versatile than hard jaws, don't kill cutters when you run a tool into to them, as well as being machinable for fixturing as needed. Make soft jaws, remove your hard jaws, and store them on the shelf.

In this case the shallow dovetail adds an extra layer of security because the part is so tall relative what I'm hanging on to, and I'm taking a 0.500 depth of cut with a 3/8 endmill. Probably doesn't need it, but only takes a couple of minutes to add the dovetail. That part is not going to come out of the vise. I just used a 14° dovetail router bit.

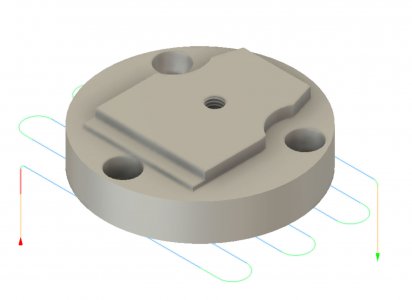

Face off, drill & tap the the holes [...]

About 0.050'' clearance above the vise jaws at closest point. [...]

And done with this side. Then over to the band saw to trim off the excess. [...]

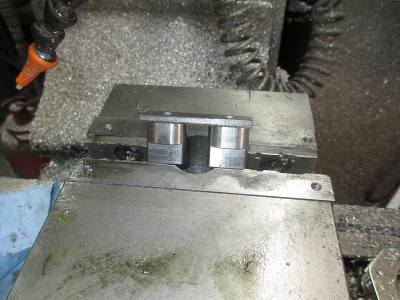

Flip over and put in the vise [...]

Chew off the 0.181'' excess material. And done.

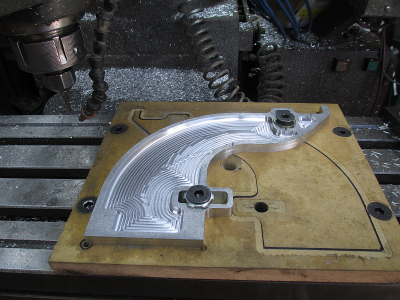

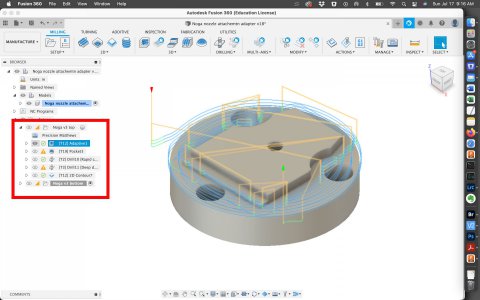

but it does give you an idea of what modern toolpaths and tooling will do.

but it does give you an idea of what modern toolpaths and tooling will do.