-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

B

BRIAN

Forum Guest

Register Today

Hi Thomas

We are probably 2 years away from that point, but I will show all the set up as it goes together, each cylinder has to be set individually.

Brian.

We are probably 2 years away from that point, but I will show all the set up as it goes together, each cylinder has to be set individually.

Brian.

B

BRIAN

Forum Guest

Register Today

B

BRIAN

Forum Guest

Register Today

With the case on the jig the other way round, I have got the case to it's final external diameter and length.

The internal diameter is very near but I will wait until it cools down, then it will be fitted to the jig adaptor ring that is on the bed in the photo.

The radial position of the case is set by a small dowel pin, you can just see the hole at 11 oc on the case edge.

Brian.

The internal diameter is very near but I will wait until it cools down, then it will be fitted to the jig adaptor ring that is on the bed in the photo.

The radial position of the case is set by a small dowel pin, you can just see the hole at 11 oc on the case edge.

Brian.

B

BRIAN

Forum Guest

Register Today

Next morning the ring is made a push fit in the case.

The assembly is now fitted to the rotary table using the ring , small dowel ,and a draw screw

The mill has not been moved from when I drilled the first dowel hole so the hole on the opposite side is drilled in the same position.

Flip over again onto the new locating dowel and fit five large dowels into the main securing holes.

and drill the main case screw holes.

The complete RT can now be turned vertical to machine the flats and locations for the cylinders.

Brian.

The assembly is now fitted to the rotary table using the ring , small dowel ,and a draw screw

The mill has not been moved from when I drilled the first dowel hole so the hole on the opposite side is drilled in the same position.

Flip over again onto the new locating dowel and fit five large dowels into the main securing holes.

and drill the main case screw holes.

The complete RT can now be turned vertical to machine the flats and locations for the cylinders.

Brian.

B

BRIAN

Forum Guest

Register Today

B

BRIAN

Forum Guest

Register Today

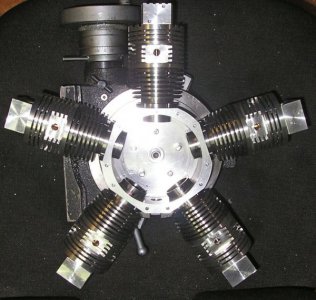

Two photo's I have been looking forward to taking.

View attachment 134130

View attachment 134131

Now for the other four.

Brian.

IMO those are significant photo's...

I am thoroughly enjoying your thread...

I doubt I have the tenacity to do that project...

And I know I do not have the time...

B

BRIAN

Forum Guest

Register Today