OK so the next stage is to prepare a mould to make the silicone rubber cup to drive the spinner and the drive assembly with a one way clutch to stop over speeding the drill used to power it.

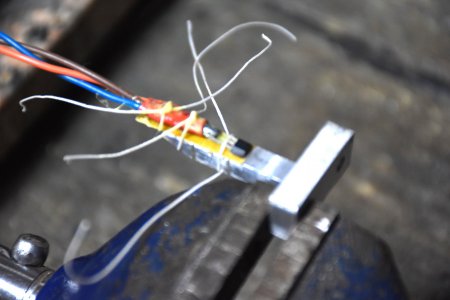

The drive assembly was made first because it formed one half of the mould for the rubber cup.

the second half was then made to match the drive and contain

the spinner to ensure a perfect fit.

The mould was then filled with preconditioned silicone and the two parts mated and left to cure for 24 hrs It is important to protect all the iron and steel surfaces because the acid produced produces heavy rust.

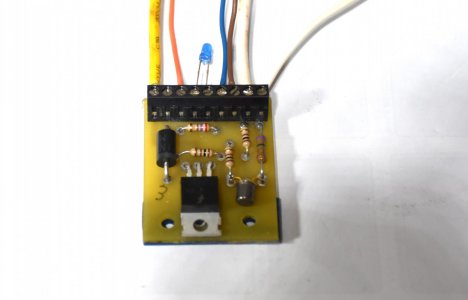

The finished drive assembly

Now we are ready for the test run.

Brian.

The drive assembly was made first because it formed one half of the mould for the rubber cup.

the second half was then made to match the drive and contain

the spinner to ensure a perfect fit.

The mould was then filled with preconditioned silicone and the two parts mated and left to cure for 24 hrs It is important to protect all the iron and steel surfaces because the acid produced produces heavy rust.

The finished drive assembly

Now we are ready for the test run.

Brian.