- Joined

- Jul 13, 2014

- Messages

- 1,054

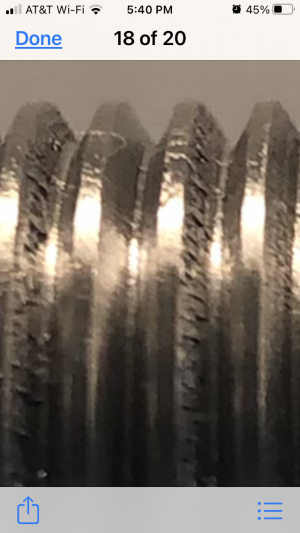

The speed for manual threading is way below the optimal speed for carbide. I suggest you try a sharp HSS tool. Grinding the tool is no big deal. Use the fish gauge as a template. Hone to a fine edge after grinding. Use a stone to create the flat at the tip of the tool.

I am not totally sold about the carbide issue on low speed manual threading. I use carbide laydown on my 90s vintage Jet 1024, and plunge it straight with the cross slide.

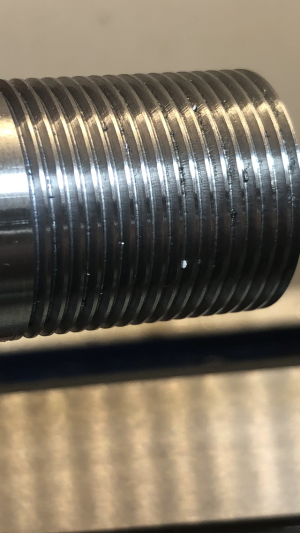

This barrel was threaded 3/4x16 to host an adapter to be turned and threaded for a 7/8x32 tuner. I cut the threads using the jog button, and that is slow. The stick out is quite long, the tuner requires 0.9 inch long thread, plus a shoulder.

I have Warner HSS threading bits and carbide special order ones from Thinbit, and a bunch of laydowns from my favorite supplier in China. I could not tell the difference on the thread quality using any of the three types.

The times when I am running 2 lathes I thread in the 1024 using the proximity sensor at higher rpm speeds with the laydown. I am not sure if I could tell the difference in the thread looks.