Episode 8 || Cylinder Barrel Trials

I’ve gone through three rounds of trying to machine some cylinder barrels, and haven’t been happy with any of them. I’m calling them “trials”, but let’s face it, they were failures. The three trials are in order in the photo below starting with Trial 1 on the left.

In all three cases, the ‘failure’ was associated solely with making the fins --- the drawings call for ten 0.040-inch-wide fins separated by 0.040-inch-wide grooves. So that’s what I’m going to focus on in this post. I’ll discuss the other aspects of making the cylinder barrels once I perfect the technique and bang out five good ones. Also, I haven’t yet made a cylinder barrel I’m happy with, so there’s a fair chance of additional ‘trials’ along the way. Who knows.

The logical way to create the fins on these cylinder barrels is using a parting tool on the lathe. Now, I’ve always struggled with grooving and parting-off on my lathe. I’ve tried grinding my own parting blades and using store-bought blades. I’ve tried narrow blades (0.040”) and wide blades (0.125”). I’ve tried lining up things to be square by eye, aligning things square using an indicator, and even purposely lining it up off-square. I’ve tried neutral-, left-, and right-cutting geometry. I’ve used high-speed steel, brazed carbide, and carbide inserts. I’ve used the “T” style, and all sorts of other styles. I’ve tried setting the tool on center, slightly above center, and slightly below center. I’ve tried power feeding and hand feeding. I’ve worked with aluminum, brass, bronze, cast iron, mild steel, and alloy steel. I often tighten up my gibs, I always choke up on the tool, and I always set the carriage lock.

I very often get a nice, consistent chip without any chatter. But I’d conservatively estimate that 90% of the time I end up with a crooked groove. Often a

very crooked groove.

I know it’s the poor craftsman who blames his tools, but it seems my lathe is simply too flexible or worn out to get decent/consistent results.

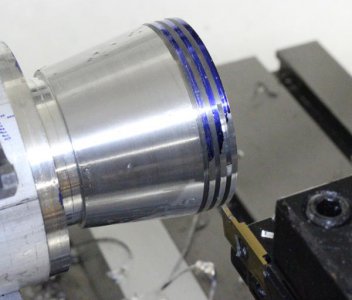

Trial 1

Because making these fins is so obviously a job for a parting tool on the lathe, that’s where I started. I used a 0.040” commercial parting blade with a V shaped profile, and squared it up to the work. I was actually getting some reasonably straight cuts and reasonably consistent fins, but some of the middle fins ended up narrower than the others, and some of the edge fins ended up tapered/bend due to the cuts wandering. When I finally parted off the cylinder barrel (using a 1/8” HSS parting blade with a neutral grind), you can see some of what I’m taking about with the wandering cuts. I was actually willing to live with this one, as it wasn’t horrible.

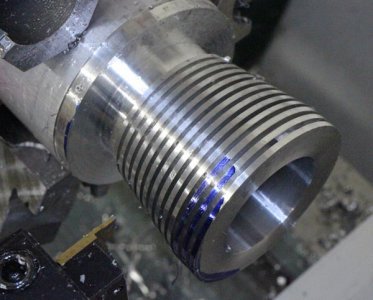

Trial 2

Trial 2

The steps for making the fins on this barrel were identical to the first trial. Same parting blade, same method of squaring it up, etc. But the results were woefully inferior. The taper is so bad that the top-most fin has zero thickness at the outermost tip, and some of the fins down lower had zero thickness at the very inside, resulting in partial or complete separation of some fins from the meat of the barrel. Completely unacceptable. The two initial cylinder barrels were going in the scrap bin, and I needed to find a better way to skin this cat.

Trial 3

Trial 3

If you can’t do it on the lathe, try it on the mill, right? I had a 0.032” slitting saw on hand, so I reckoned I’d give that a go. It wasn’t the specified 0.040” thickness required, but it was close enough for a trial run. For those who have read my past posts, you may know that my Bridgeport has some very modest CNC capabilities; among those capabilities is tracing out a circle in X/Y space, which is exactly what I needed to cut these fins. (Though if I had a rotary table, that’s probably what I would have used instead. But I don’t have one.) So I machined out a blank on the lathe, brought it over to the mill, and went at it with the slitting saw. The results?

Excellent! But then I pushed it too hard and ended up shattering the blade, rendering the part a complete loss… oh well.

I was able to get 2.5 of the grooves cut with the slitting saw before it shattered, and it yielded crisp, sharp results. Great!

I ordered a couple 0.040” slitting blades and plan on milling out the fins for the cylinder barrels. I think this is actually ideal, as similar fins are called for on the heads which

cannot be cut using a parting blade on the lathe. So doing everything with the same slitting saw using the same equipment should give me an overall more consistent look.

So that’s the plan going forward. Slitting saw on the mill, take it easy on the cutter, and use plenty of lube.

TIME ON CYLINDER BARREL TRIALS: 9.5 hours

CUMULATIVE TIME: 100 hours