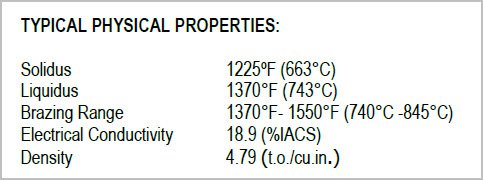

I'm glad we had this conversation. How did I miss your silver 'brazing' post? BTW I used Harris Stay-silv white flux & Saftey-Silv-45 brazing filler metal. I concur with your comment about melting temp, its stated on the spec sheet. You made a very good point about 'interference engine'. I'm pretty sure this radial is the same, so I'll confirm that. That removes a lot of handwringing if any of the timing gears lets go.

OK I'm going to have to plan my next step about some kind of retention pin for the CS gear. Getting accessibility to the rear bearing for eventual replacement is almost a certainty based on any methanol fueled glow engine I've ever met.

OK I'm going to have to plan my next step about some kind of retention pin for the CS gear. Getting accessibility to the rear bearing for eventual replacement is almost a certainty based on any methanol fueled glow engine I've ever met.