- Joined

- Mar 9, 2018

- Messages

- 461

Episode 18 || Rocker Brackets

Short one today.

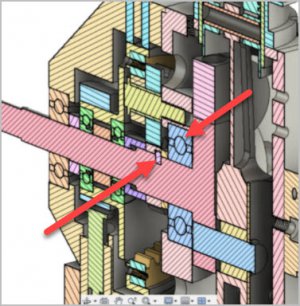

The rocket brackets were straightforward to make. They’re attached to the heads with one #4-40 SHCS each, located (and counterbored) just beneath the rocker.

My Fusion 360 model doesn’t have the rocker shaft, but it’s a 1/8” headed dowel pin --- a so-called ‘captive pin’ --- which I purchased from McMaster. See also my post from a few days ago about why I chose to go this route.

I started with a chunk of 7075 aluminum big enough to get all the brackets. With the overall block of aluminum milled to the correct overall dimensions, I just hack-sawed a slab for each of the brackets, then milled each of those to final size.

Then I milled the radius (using an ‘arc’ routine on my 2-axis CNC-lite Bridgeport) and drilled/reamed the 1/8” hole for the rocker pin.

After milling out the middle section for the rocker, I drilled and counterbored for the #4-40 SHCS.

A bit of clean-up and debur and they’re ready to mount on to the heads. These are pretty tiny --- 1/4” thick x 1/2” wide.

As a side note, the finish on the rocker arms is atrocious. I intend on cleaning that up with some emery cloth / files at some point. But there’s a pretty fair likelihood that I won’t end up doing that. We shall see.

Also, I don’t really like the looks of how the rocker brackets extend out past the heads like they do. They just look scabbed on there to me. I’ve thought this since I started the build but figured I’d make a design change when the time came. Well. That time came and went, and I ain’t gonna change it.

TIME ON ROCKER BRACKETS: 9 hours

CUMULATIVE TIME: 353 hours

Short one today.

The rocket brackets were straightforward to make. They’re attached to the heads with one #4-40 SHCS each, located (and counterbored) just beneath the rocker.

My Fusion 360 model doesn’t have the rocker shaft, but it’s a 1/8” headed dowel pin --- a so-called ‘captive pin’ --- which I purchased from McMaster. See also my post from a few days ago about why I chose to go this route.

I started with a chunk of 7075 aluminum big enough to get all the brackets. With the overall block of aluminum milled to the correct overall dimensions, I just hack-sawed a slab for each of the brackets, then milled each of those to final size.

Then I milled the radius (using an ‘arc’ routine on my 2-axis CNC-lite Bridgeport) and drilled/reamed the 1/8” hole for the rocker pin.

After milling out the middle section for the rocker, I drilled and counterbored for the #4-40 SHCS.

A bit of clean-up and debur and they’re ready to mount on to the heads. These are pretty tiny --- 1/4” thick x 1/2” wide.

As a side note, the finish on the rocker arms is atrocious. I intend on cleaning that up with some emery cloth / files at some point. But there’s a pretty fair likelihood that I won’t end up doing that. We shall see.

Also, I don’t really like the looks of how the rocker brackets extend out past the heads like they do. They just look scabbed on there to me. I’ve thought this since I started the build but figured I’d make a design change when the time came. Well. That time came and went, and I ain’t gonna change it.

TIME ON ROCKER BRACKETS: 9 hours

CUMULATIVE TIME: 353 hours