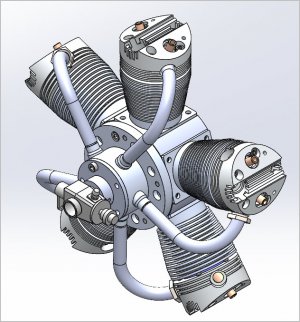

Episode 15 || Rocker Arms

Well it’s hard to believe that I haven’t made any progress on my Edwards in a year. Time flies when you have two small children, a full time job, and are dealing with an ongoing worldwide pandemic. I guess I’ll forgive myself. I’m excited to get back into the swing of things.

I started making these rocker arms over a year ago and just recently finished them off, so the early stages of making them are a bit blurry. They’re shown in the drawings with fairly complex geometry, but that’s mostly just for the look. None of the dimensions are all that important, which is good, because I wasn’t all that accurate in making them.

Steps 1/2

Steps 1/2 -- I used a regular hacksaw to cut out 12 blanks from a plate of 7075-T6 aluminum. Only 10 are needed for the engine, but ya know… screw-ups and such. Then I squared them all up on the Bridgeport to the overall dimensions.

Steps 3/4

Steps 3/4 -- I clamped each part sequentially in the vise and milled out the overall profile using the modest 2-axis CNC capabilities on my Bridgeport. Mostly I used the CNC to get the radii put in without having to deal with a rotary table. These are all non-critical features, so I could have done it all with a file and been fine. Then I drilled/reamed and drilled/tapped the two ‘vertical’ holes in the same setup.

Steps 5/6

Steps 5/6 -- I made up a little fixture plate from some scrap aluminum to machine out the next features. It has a dowel pin hole corresponding to the reamed hole from Step 4. I used this fixture to drill/ream the rocker pivot holes.

Steps 7/8

Steps 7/8 -- Fast forward an entire year. I used the same fixture block to carve out the bottom side of the rocker arms. They were again located in the fixture block with a dowel pin, and were secured with a 4-40 screw through the rocker pivot hole. Last step was to modify the fixture a little and machine the tapered part on the top of the rocker arm.

They’ll need a lot of cleanup/debur/etc., but they look great! Here are half ready for the last step, and half fully complete. Bottle cap for scale. Again, only 10 are needed, but all 12 made the journey from raw stock. I’ll pick the two worst ones and keep them as spares.

The next major component will be the heads. They’re the most complex part of the build and I’m looking forward to getting right back into the swing of things.

TIME ON ROCKER ARMS: 14 hours [split about 50/50 in 9/2020 and 9/2021]

CUMULATIVE TIME: 265 hours