Well, I have snugged up the cross slide nut a bit.

First, I had to make a pin press to remove the roll pin holding the handle on to the cross feed screw. Then the roll pin came right out and I didn’t risk bending the shaft by trying to hammer it out.

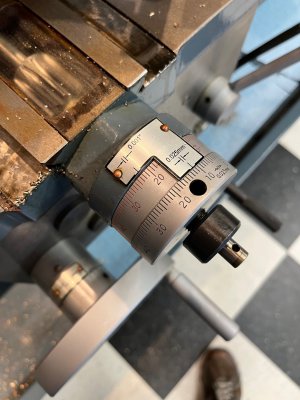

That black collar between the handle and the cylinder with the ruled scales ( Imperial and metric, the screw is 8 TPI) is actually the nut holding the screw in place against the thrust bearings. It is locked by a grub screw. Once I loosened the nut the cross feed screw was also loose. It seems to me that way the it was factory assembled it was to tighten the nut until the play was gone, but no more. This allowed the cylinder with scales to be rotated and “zeroed” by the operator. I almost never zero it as this requires an Allen wrench in a deep counter bore. Any way, I snugged the nut down to where the torque needed to rotate the crossfeed screw felt “right”.

Then I drilled and tapped a ¼-20 thread in the handle for future installation of a second handle or counter weights.

Assembled and tested with a number of cuts on some 1.5 inch diameter round steel stock. The handle stayed right where I put it on every cut. Very nice. I’ll call that success.

(For scale in the images, that black collar is a bit over an inch in diameter. The handle is made from 20 mm square steel.)