- Joined

- Dec 25, 2017

- Messages

- 167

I am seeking advice on a long-standing issue with my lathe. What I have is an Enco 13x40 built in 2006. I bought it new.

Since new it has had an annoying habit of letting the cross slide feed handle back off counter clockwise when the “stick” on the handle is oriented such that gravity pulls it down. It will “fall” until the backlash on the screw is taken up. The problem matters while doing a turning operation. If I set the cross slide for a fresh cut and that happens to be where the “stick” handle is on the left side, then if I let go of the cross slide feed handle the handle will rotate CCW by gravity. This CCW rotation removes the screw pressure holding tool pressure on the cross slide. Then the cross slide moves away from the workpiece until the screw is engaged again. If I HOLD the handle, all is fine.

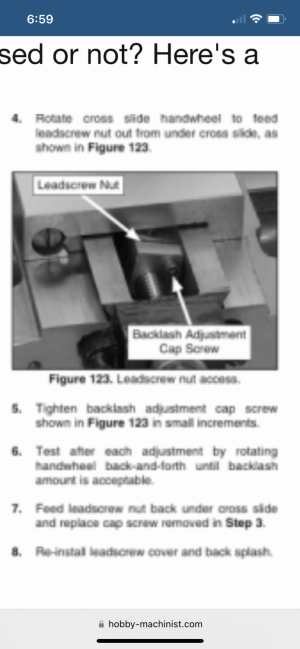

Note that I am not describing a backlash issue. The backlash is set by a split nut with wedge to 0.009” at the moment. The root issue is the handle and screw rotating CCW when the “stick” is on the left side and can thus move down by gravity.

I can see two paths forward:

1) Balance the wheel. Attach weight to the non-handle side.

I see that fancier lathes have balanced wheels. But some really nice machines don’t.

2) Try to increase the friction of the screw rotation.

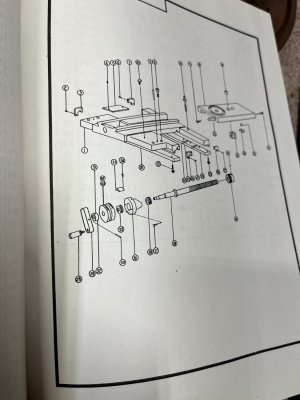

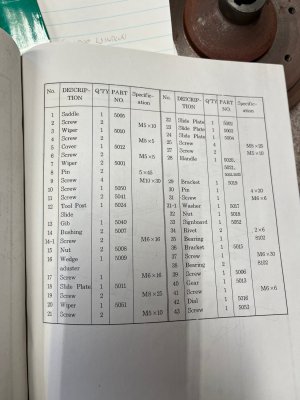

The parts diagram (below) shows the screw is supported by a pair of opposed thrust bearings. I suppose I could tighten the nut and hope for more friction. It could be that all I get is over tight bearings with lumpy rotation.

Any suggestions or advice? Have any of you fixed this problem or your machine?

Since new it has had an annoying habit of letting the cross slide feed handle back off counter clockwise when the “stick” on the handle is oriented such that gravity pulls it down. It will “fall” until the backlash on the screw is taken up. The problem matters while doing a turning operation. If I set the cross slide for a fresh cut and that happens to be where the “stick” handle is on the left side, then if I let go of the cross slide feed handle the handle will rotate CCW by gravity. This CCW rotation removes the screw pressure holding tool pressure on the cross slide. Then the cross slide moves away from the workpiece until the screw is engaged again. If I HOLD the handle, all is fine.

Note that I am not describing a backlash issue. The backlash is set by a split nut with wedge to 0.009” at the moment. The root issue is the handle and screw rotating CCW when the “stick” is on the left side and can thus move down by gravity.

I can see two paths forward:

1) Balance the wheel. Attach weight to the non-handle side.

I see that fancier lathes have balanced wheels. But some really nice machines don’t.

2) Try to increase the friction of the screw rotation.

The parts diagram (below) shows the screw is supported by a pair of opposed thrust bearings. I suppose I could tighten the nut and hope for more friction. It could be that all I get is over tight bearings with lumpy rotation.

Any suggestions or advice? Have any of you fixed this problem or your machine?