- Joined

- Oct 7, 2020

- Messages

- 2,442

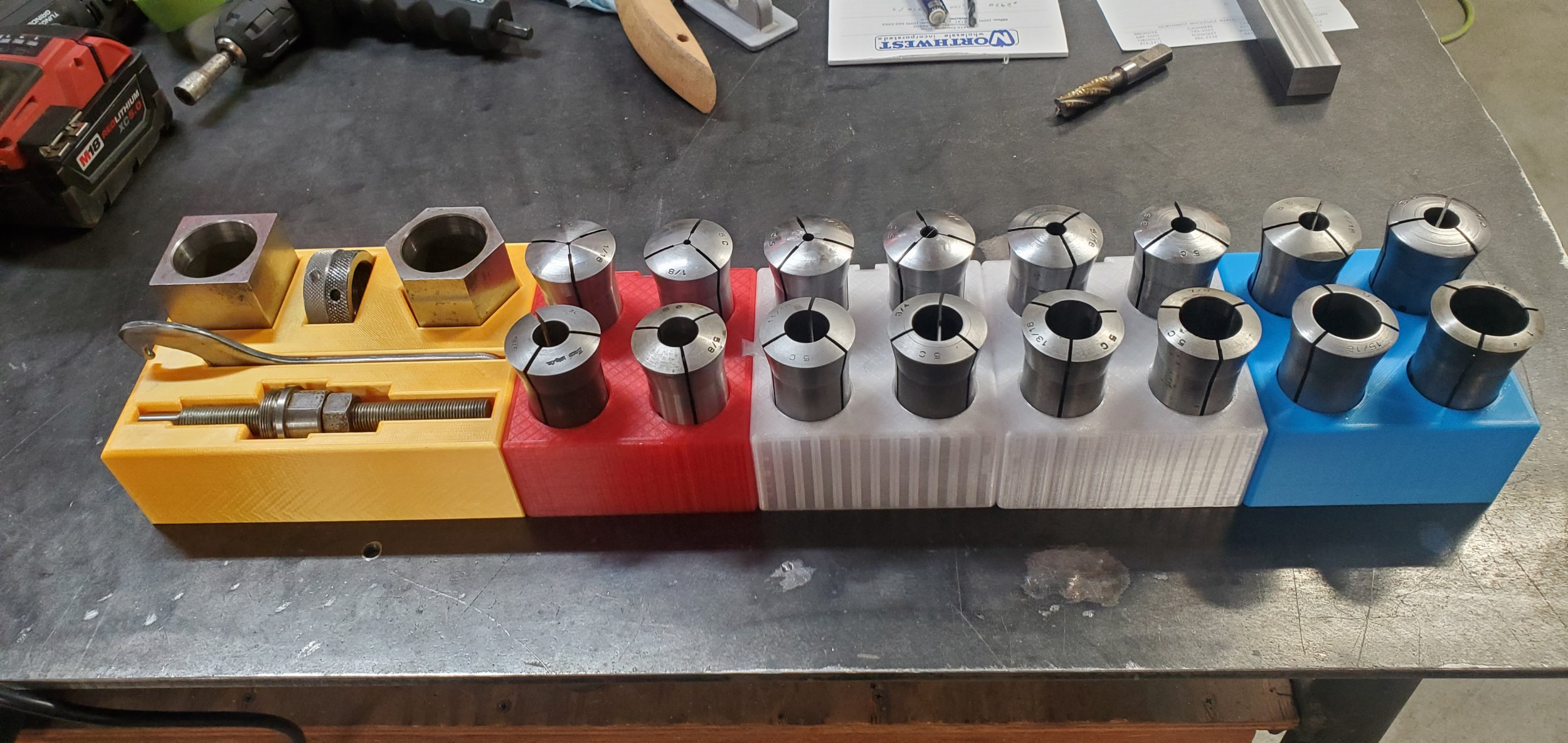

My 5C collet holders. I grabbed the red, white and blue ones from printables and yellow I designed in Fusion. They all fit in a drawer in my tool box.

I was testing my CAD abilities out with a print in place model a few days ago. It was tougher than I expected.

It took me a half dozen prints to get the air gap between moving parts just right. With PLA it works very well, albeit a bit tight to get the moving parts broke loose without breaking it. The "general rule" of double the layer height is a starting point. You definitely gotta tweak it from there to fit the material. For standard PLA, I ended up with just i little more than double the layer height to get it to work.

I made good use of Alibre Design's equation editor with this one, to create parameters than could be changed and re-exported on the fly.

Unfortunately, when I print one in PETG, ABS or silk PLA the air gap dimensions change and it's either locked up solid, or too loose to be useable. It would seem that the air gaps need to be tuned to a specific material. One of these weekends I may print/test and adjust the parameters to get some PETG and ABS versions.

View attachment 425353Chip clip by Ken226 | Download free STL model | Printables.com

This is a locking, sharp toothed lever cam operated bag clip. One print, 3 moving part | Download free 3D printable STL modelswww.printables.com

The front and rear "extra" parts are snap-off support tabs. They print in place with the model, then are snapped off and thrown in the trash.

View attachment 425354

But, we don't buy chip clips anymore :}

On tool storage, I modified my MT3 tailstock rack to create a R8 versions. I have one running in silver silk PLA now. 15 hours to go.

Thingiverse website seems to suck lately. I started uploading my modes to Prusa's version, Printables.

R8 version of my 3034 Lite Rail, tool holder. by Ken226 | Download free STL model | Printables.com

This is a modified R8 version of my 3034 Lite Rail MT3, tool holder. This one holds R8 collets, end mill holders, etc. | Download free 3D printable STL modelswww.printables.com

@Ken226 WOW you have a lot of stuff on printables.

Love it!I suck at CAD, and figured the best way to get better is to buy something expensive that requires I get better with CAD. My Bambu X1-Carbon arrived a few weeks ago, and my voyage to get the shop organized and clean has started.

I bought several lots of used machine tools, and they came with crates and bins of tooling and accessories, but not much for organizing.

I spent a "few" hours modeling and printing holders for my collet extensions and collets; 100DA, 200DA and ER16. This is much nicer that the "2x4 with holes drilled in it" method the previous owner used. It's also able to fit in a drawer.

View attachment 494283I'm printing in black PLA, but waiting on my order of gray to show up; I think it'll make the drawers a bit brighter.

I suck at CAD, and figured the best way to get better is to buy something expensive that requires I get better with CAD. My Bambu X1-Carbon arrived a few weeks ago, and my voyage to get the shop organized and clean has started.

I bought several lots of used machine tools, and they came with crates and bins of tooling and accessories, but not much for organizing.

I spent a "few" hours modeling and printing holders for my collet extensions and collets; 100DA, 200DA and ER16. This is much nicer that the "2x4 with holes drilled in it" method the previous owner used. It's also able to fit in a drawer.

View attachment 494283I'm printing in black PLA, but waiting on my order of gray to show up; I think it'll make the drawers a bit brighter.

Hey David, Your holders look great. How did you get the look on the surface?

Those are great!

I’ve started down the Gridfinity path to organize my lathe and mill tooling.

Here a few examples.