- Joined

- Mar 31, 2016

- Messages

- 106

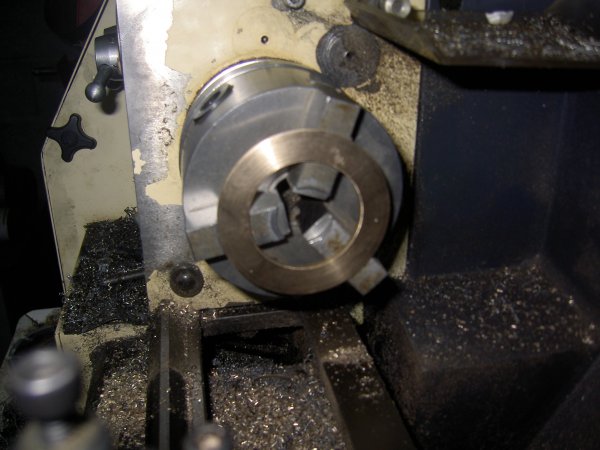

I will remember it! I was surprised how much difference that small rise in temp made. The plate was turned around on the lathe and faced, I think it is still a bit thick and I might reduce it. I made some end float shims

next from a bit of bronze I had left over from a project I did some 25 years ago, I made a 70ft narrow boat which I made from scratch, the prop shaft was from an industrial potato peeling machine and the bushes were re-

worked by a friend of mine and used in the stern tube, and this is the off cut. It is about a mil big on the internal dia but it will be fine. They needed to be 2mm thick, turning them to thickness I needed to cut a grouve in some

soft jaws that were not soft and the blue chips burn!!

The shims are for the end float on the main spindle. This is the head as far as I have got to date.

I am not completely happy with the face plate it seems a little to thick and those marks on the rim look a lot worse on the pics than in life but they could do with a bit of a clean up. I decided

to go with four holes to mount the division disc so the discs couold be rotated to keep the no. of hole identifying numbers up right in the three most important positiond of the head, 0 45 and 90 degs.

The shim I have just made goes between the spindle clamping plate and the main barrel but bears on the shoulder of the spindle not the clamping plate.

next from a bit of bronze I had left over from a project I did some 25 years ago, I made a 70ft narrow boat which I made from scratch, the prop shaft was from an industrial potato peeling machine and the bushes were re-

worked by a friend of mine and used in the stern tube, and this is the off cut. It is about a mil big on the internal dia but it will be fine. They needed to be 2mm thick, turning them to thickness I needed to cut a grouve in some

soft jaws that were not soft and the blue chips burn!!

The shims are for the end float on the main spindle. This is the head as far as I have got to date.

I am not completely happy with the face plate it seems a little to thick and those marks on the rim look a lot worse on the pics than in life but they could do with a bit of a clean up. I decided

to go with four holes to mount the division disc so the discs couold be rotated to keep the no. of hole identifying numbers up right in the three most important positiond of the head, 0 45 and 90 degs.

The shim I have just made goes between the spindle clamping plate and the main barrel but bears on the shoulder of the spindle not the clamping plate.