- Joined

- Nov 23, 2014

- Messages

- 2,634

POTD was making a cap for the end of a debugging tool. I was using the tool to deburr the Delrin flange benders from the POTD post above and noticed some of the bits on the floor (after my annual sweeping of the shop . . .). The cap had a hole in the end. Extra bits are stored in the handle. The tool neck length is adjustable, the cap probably broke from me pushing down and driving the arbor through the bottom of the cap.

Chucked up a piece of 1” 6061 aluminum and turned a new cap. Steps are in the photos below. Figured I’d go with aluminum instead of plastic so I don’t blow a hole in the cap again.

Thanks for looking, Bruce

Blew a hole in the bottom of the deburring tool

Facing a 1" aluminum round

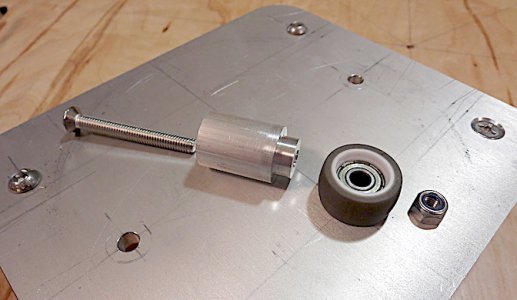

Cut a shoulder for the 0.872 x 10 tpi thread

Center drill

1/2" clearance hole in the cap

Boring the hole to a flat bottom

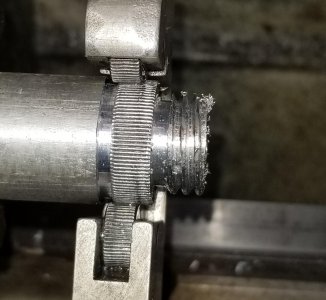

Relieved the base of the thread with a parting tool

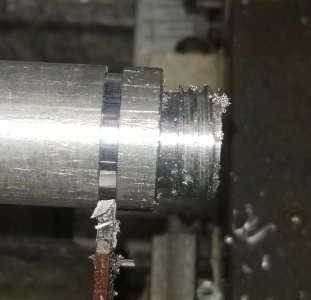

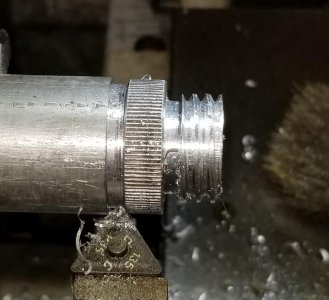

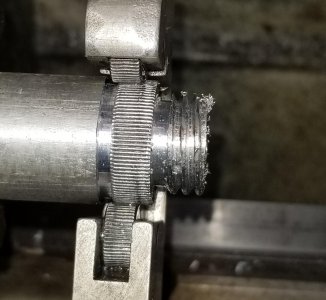

Scratch pass, verified 10 tpi with a thread gauge

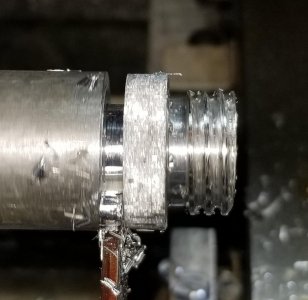

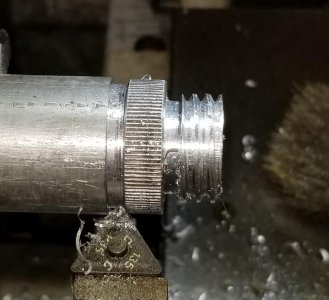

Last pass.

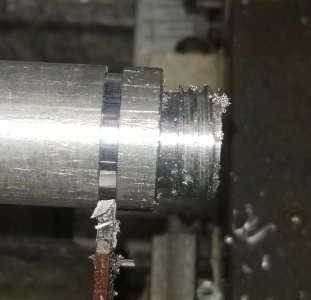

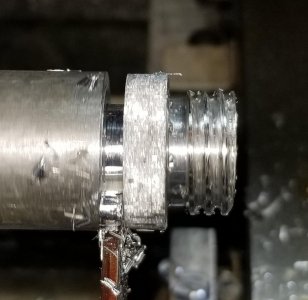

Pre-parting the end of the cap in prep for knurling

Knurling the cap with a Rockwin Knurlmaster hand knurling tool

Put a little chamfer on the cap edges

Parting off the cap

Set up on my Clausing lathe for facing the end with a 5 deg. angle. No DRO on the Clausing; measure movement in the Z-axis with a 2" travel dial indicator.

Cut the 5 deg. angle on the end of the cap

Could of sworn there were 4-6 bits in the deburring tool . . .

Better than new

Chucked up a piece of 1” 6061 aluminum and turned a new cap. Steps are in the photos below. Figured I’d go with aluminum instead of plastic so I don’t blow a hole in the cap again.

Thanks for looking, Bruce

Blew a hole in the bottom of the deburring tool

Facing a 1" aluminum round

Cut a shoulder for the 0.872 x 10 tpi thread

Center drill

1/2" clearance hole in the cap

Boring the hole to a flat bottom

Relieved the base of the thread with a parting tool

Scratch pass, verified 10 tpi with a thread gauge

Last pass.

Pre-parting the end of the cap in prep for knurling

Knurling the cap with a Rockwin Knurlmaster hand knurling tool

Put a little chamfer on the cap edges

Parting off the cap

Set up on my Clausing lathe for facing the end with a 5 deg. angle. No DRO on the Clausing; measure movement in the Z-axis with a 2" travel dial indicator.

Cut the 5 deg. angle on the end of the cap

Could of sworn there were 4-6 bits in the deburring tool . . .

Better than new

Attachments

Last edited: