POTD was a follow-up on the prototype Ergonomic /flange bender tool from a previous POTD post. I put the wooden prototype over the door part and needed to make a couple of tweaks before cutting the Delrin final tools. Here's the link to the original post:

I put new solar lights in around the house , started on a garden project requiring 48 landscape ties , and found these down the other basement while looking for a 1"-8 tap . :grin: Enco 4" boring/ facing head and another Geometric die head .

www.hobby-machinist.com

Problem was the part that the “U” section slips over is wider at the base than at the spot where the tool pushes against. The tool rocked enough that it tended to slip off on the back side. Simple fix, lengthened one leg and added a radius “chunk” on the end so the point where it touches and reacts against on the back side are parallel to each other, so no slipping.

The tools will be used on both sides of the assembly line, so made five which gives us a few back-ups. The CNC routine is stored on my Tormach so no problem making more if need be.

Thanks for looking, Bruce

Block of Delrin in the Tormach 1100 cutting the new profile

View attachment 302871

Secondary operation to cut a boss on the end which slips into a piece of tubing for a handle.

View attachment 302872

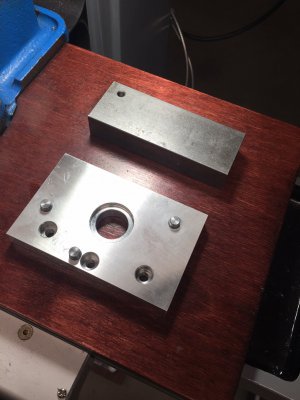

Final flange bender / Ergo tool

View attachment 302873

Made up 5 for our floor. We'd measured as high as 45 lbs. of effort to seat the part which is way over the Ergonomic limit of 20 lbs. The length of the handle maths out to a force of 8 lbs. at the end to get 45 lbs. at the reaction surface, so no sore thumbs for our Team Members.

View attachment 302874

Front glass run channel for the Buick Enclave. The upper clip in the photo was tough to seat. Solution is the simple machine of a lever so no one goes home sore at the end of the day.

View attachment 302877

Slip the tool over the glass run channel and give a little push on the end to seat the clip.

View attachment 302875

View attachment 302876