- Joined

- May 27, 2016

- Messages

- 3,469

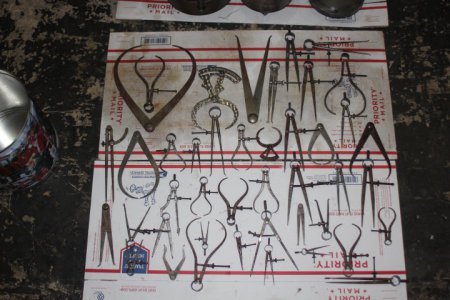

This is the kind of thing where we want someone who knows to tell us why this happens!The is a good chance the the spring steel hoop at the top will fall into pieces if left to soak in Evaporust. Not always ,but it does happen. Don't know what you want to call it. I have had a pair fall apart in an overnight bath. The spring steel fell into pieces. Also it will ruin the finish on gauge blocks. Just my experience.

If it happens with a chelation agent like EvapoRust, then it might well happen with almost any other chemical rust removal procedure, including those urged on with a voltage.