OK, I got switches in. They aren't what I thought I was ordering. I won't say they weren't as described (but they weren't).

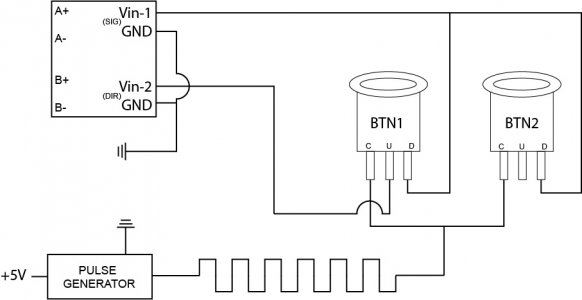

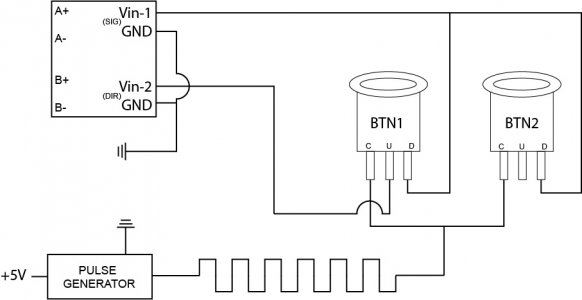

The switches were supposed to be momentary. They are single pole, 2 way, latching switches. Which, if they weren't latching switches, it would be easier to hook up as the illustration shows. In the up position the U (up) connection is made. In the D (down) position, the U disconnects and the other connection is made. C is, of course, common and would be coming from the pulse generator.

When both switches are up, only the *dir* gets power and that should be just fine. Then if pressing button 1, the dir is powered and the step signal goes to the driver.

However, if BTN 2 is pressed, instead, the power to *dir* is cut and the step signal goes to the driver.

This would reverse the motor, right?

My brain wants to say there's a way to do this without the *dir* getting power all the time when nothing is pressed but I'm not seeing it right now without adding electronics (a simple flipflop would do it)