- Joined

- Feb 24, 2019

- Messages

- 927

For whatever reason I can never wrap my head around diodes.

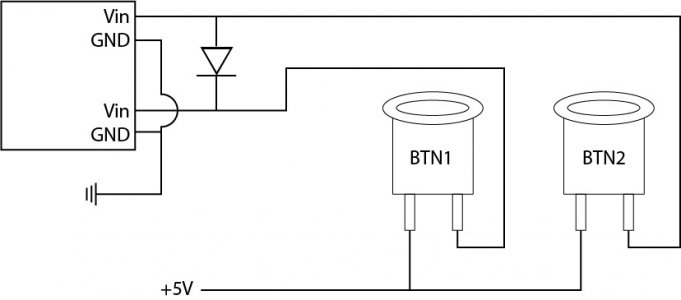

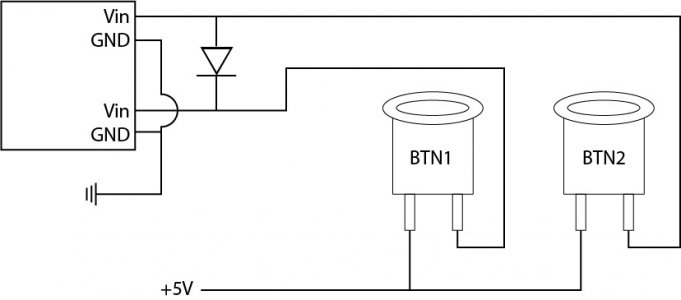

In the following schematic, I want to control both inputs with one button but only one input with the other.

What does this circuit do?

Is there a better, easier, way to accomplish this?

The diode is to keep the backflow out of the equation.

In the following schematic, I want to control both inputs with one button but only one input with the other.

What does this circuit do?

Is there a better, easier, way to accomplish this?

The diode is to keep the backflow out of the equation.