- Joined

- Feb 24, 2019

- Messages

- 927

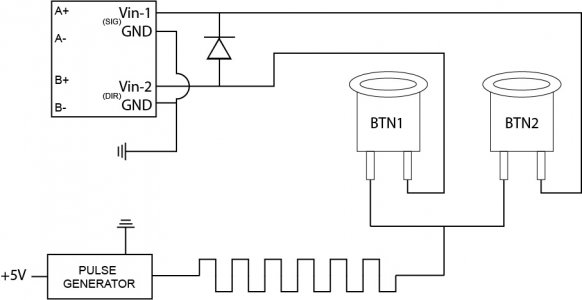

I will have a small control panel to set the frequency of the pulses to the driver. The schematic above was, as said, very simple.Forgive me for asking, but are you sending command pulses to the driver, or trying to control it with switched power only?

Basically the frequency generator will be on all the time when I'm using the machine. The buttons will just tell the pulses where to go.