- Joined

- Jan 4, 2021

- Messages

- 1,814

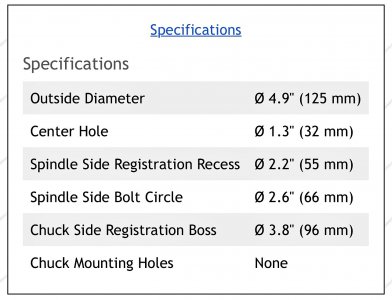

Accusize 5" 3-Jaw Chuck Fitting, Part 1

Part 1 is now live on YouTube! Please like and leave comments on YT; questions are always welcomed both here and on YT.

Part 1 is now live on YouTube! Please like and leave comments on YT; questions are always welcomed both here and on YT.