- Joined

- Sep 13, 2013

- Messages

- 276

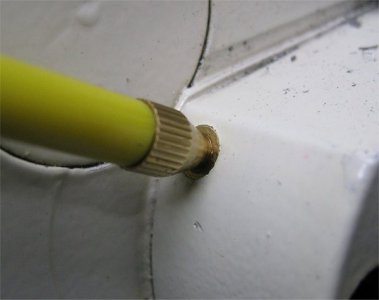

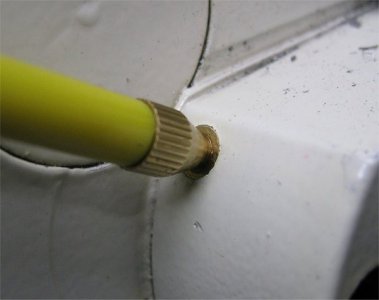

A pice of 3/16 vacum line or gas line over the tip of your favoret oil can will seal and alow the oil to flow in.

OK...that's something else to try.

Thanks

A pice of 3/16 vacum line or gas line over the tip of your favoret oil can will seal and alow the oil to flow in.

...really sick of my leaky Golden Rod oiler... applied clear silicone in all the areas I suspect leakage from