- Joined

- Aug 6, 2015

- Messages

- 3,887

Well... if I was going to be recovering in a room in the house... might as well do it in Ocala where I can sneak out and do a few things...

@paulymorph , got here and took the measurements you needed... let me know what else you might need... it is all apart...

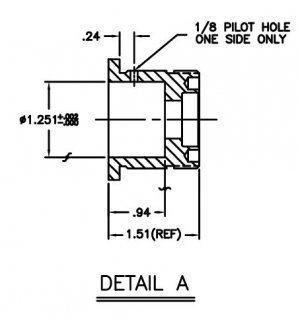

The extension:

2.8125" in total

1.9400" just the extension without the threads

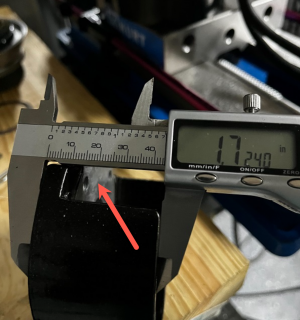

The cover that matches the dial... 1.7240"

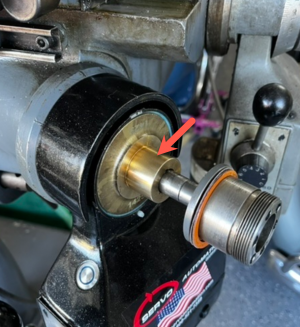

The thickness of the head of my servo...

On other news... also got the shaft out... I was careful to align the front key down... following the new shaft. So the key inside would face up, to avoid the key falling off... But guess what!!?? The old shaft has them in the same side... not opposite... So I still ended up with the key slot facing down... sigh...

Also going to order that bearing... might as well install a new one while I am at it...

@paulymorph , got here and took the measurements you needed... let me know what else you might need... it is all apart...

The extension:

2.8125" in total

1.9400" just the extension without the threads

The cover that matches the dial... 1.7240"

The thickness of the head of my servo...

On other news... also got the shaft out... I was careful to align the front key down... following the new shaft. So the key inside would face up, to avoid the key falling off... But guess what!!?? The old shaft has them in the same side... not opposite... So I still ended up with the key slot facing down... sigh...

Also going to order that bearing... might as well install a new one while I am at it...

Last edited: