- Joined

- Apr 28, 2014

- Messages

- 3,590

Is it possible that there is a GFCI somewhere in the circuit that would cause this problem?

funny you should mention that ....you are the second person to recommend Red.John, there is an old-fashioned electric motor shop over here in Bremerton called Red's Electric Motors. They have a great reputation. If you ever cross the bridge to the peninsula, you should stop by and have them take a look at it. It may not cost as much to rebuild as you think, and it would certainly cost less than a new motor. The oldies are goodies.

Silverchips: like an idiot, I did not insist he start it up. He assured me when he tried it (after cleaning), it worked fine,and he didn't explain what the problem was, only that it worked fine (how stupid could sdI get). So, according to the tech it worked at the shop, but it consistantly trips breakers (GFI) when I turn it on in the shop.

to all: anyone pursued the idea of a servo motor for these?

PS....Thank you all.

I’m in Asheville. Have you opened the connector box. Check for bare wire or a neutral hot swap.NC Rick: thanks! where in NC? I was born/raised in Wilmington (70 yrs ago!)

DavidR8: after the response here, I'd feel awful if I did let it go! Some great advice here.

mmcmdl: you would have been #2!

cluelessnewb: just contacted surpluscenter and got 2 recommendations...at under $250....it's a consideration, for sure..I installed an adjustable belt some time ago.

HarryJM: Both with/without belt attached trips ....pluged in my Jet lathe w/no issue....just bookmarked both recommeded sites (TY)...per the data plate the FRAME size is 118E ..the attachment points to the head are slots (2"..pretty adjustable)...tried multiple cords and direct plug in.

7milesup: yessir, now not gonna give it up!

matthemupet2: did you get my last?

ThinWoodsman: thought of Granger, but would REALLY like to maintain the W/T badge!

Brno: thanks for the nice welcome...and again, now I plan to keep and pass on to my son (assuming he can still spell "drill press"....

Silverchips: like an idiot, I did not insist he start it up. He assured me when he tried it (after cleaning), it worked fine,and he didn't explain what the problem was, only that it worked fine (how stupid could sdI get). So, according to the tech it worked at the shop, but it consistantly trips breakers (GFI) when I turn it on in the shop.

to all: anyone pursued the idea of a servo motor for these?

PS....Thank you all.

I want that motor! Cool.no worries, the perils of humour on the internet

well, that turned into a bit of a palaver. Took the motor off the shelf, weighed it and then turned it on to check to see if it was still good. It wasn't - it made a nasty bearing noise and wouldn't turn off at the switch.

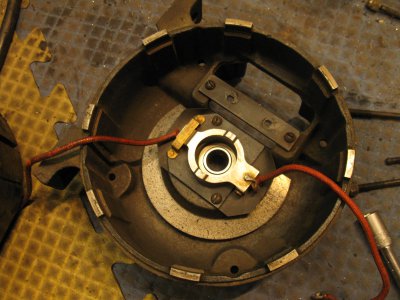

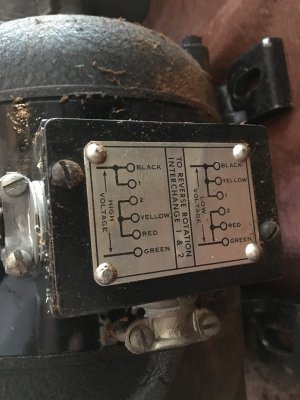

So, took it to pieces, found that the bottom (non pulley) bearing had a busted cage. Found a good replacement that fit the OD and ID (6202Z), but was 50 odd thou to thin, so made a spacer to take up the slack and pushed the new bearing in. Cleaned the centrifugal switch contacts, cleaned and oiled the kickout thingy, whatever that's called. Cleaned it out the end bells, blew out some probably decades old dust, put it back together (which took a little head scratching) and it runs beautifully.

Some pics

View attachment 342479

View attachment 342480

View attachment 342481

and a movie if I can figure out how to do that. Hmm, it'll have to be a Youtube vid:

I'd like $75 for it plus shipping. That might be a killer though, it's pretty heavy (32lb + packaging). Boxed dimensions will be around 12 1/2 x 9 x 9", maybe a bit more. Zipcode is 78254. UPS does large flat rate boxes for a decent price, so that might be worth checking out if you're interested?

Oh, and I even that the original square head nuts