- Joined

- Nov 7, 2019

- Messages

- 483

Trying to not overdo it since my elbows are about to explode from all this manual labour, definitely not used to all this wheeling, manipulating and hammering.

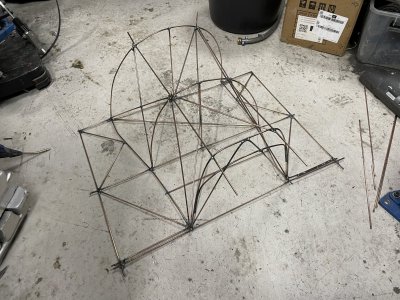

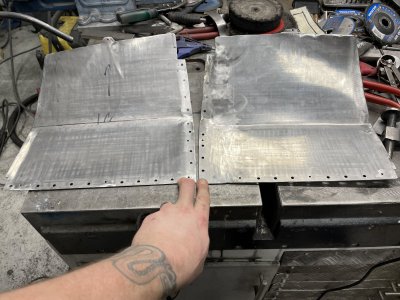

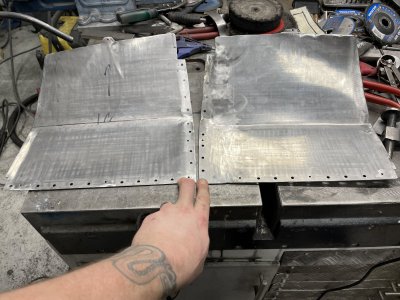

Made a rough mirrored piece to the first part, for the drivers side.

The perimeter is a bit different since the surrounding sheet is cut a bit different so it looks more "off" than it really is.

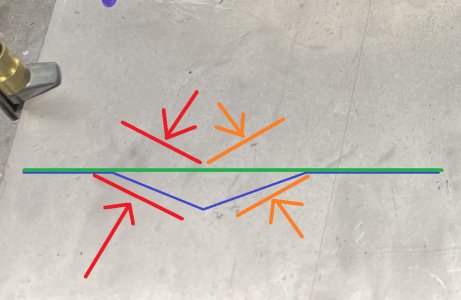

Decided to beadroll it like this, as deep as possible with the widest wheel I had.

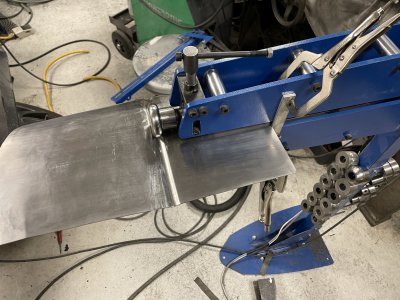

My beadroller, despite looking quite stout, definitely did NOT like this..

Not only did the wheels have a tendency to slip sideways and not stay where I set them, causing varying widths on the beads, but the frame also kept twisting a bit out of alignment causing one wheel to go ahead of the other.

Definitely need to weld on some more material if I want to keep rolling 1.25mm sheet(I know it's quite thick for work like this).

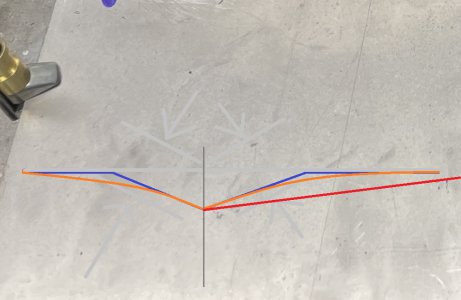

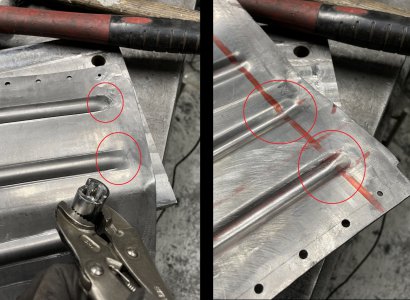

I "coined" all the beads as shown in the previous photo. Never tried this before but got inspired by some youtube video.

Gave it a quick "hack level try" by grinding out a socket and cutting half off as I didn't feel like starting the lathe and making tools.

The socket was surprisingly soft and quickly deformed from the hammer blows but it did it's job on the sheet.

Even tho the result is far from perfect I still prefer it to the "un-coined" beads that just smear back into the main sheet where they end.

Definitely need to make a proper tool that's easier to use, with this setup I was trying to hold the sheet with my hip, socket with left hand and hammer with my right hand, hence all the weird marks where they shouldn't be.

And this is what the inside looks like now.

I didn't pre-stretch before I beaded them which caused a lot of warping, definitely need to pre-stretch when you've already meticulously shaped the pieces to fit perfectly...

Caused quite a bit of work afterwards with hammer and "hand manipulating" to get it to fit. It's not as good as it was before but still fits in pretty OK.

Most of the clecos sit in 3mm holes in both plate and frame and only required a little force to get all of them in.

Pretty stoked about finally having a little bit of floor after almost 3 years or something.

Made a rough mirrored piece to the first part, for the drivers side.

The perimeter is a bit different since the surrounding sheet is cut a bit different so it looks more "off" than it really is.

Decided to beadroll it like this, as deep as possible with the widest wheel I had.

My beadroller, despite looking quite stout, definitely did NOT like this..

Not only did the wheels have a tendency to slip sideways and not stay where I set them, causing varying widths on the beads, but the frame also kept twisting a bit out of alignment causing one wheel to go ahead of the other.

Definitely need to weld on some more material if I want to keep rolling 1.25mm sheet(I know it's quite thick for work like this).

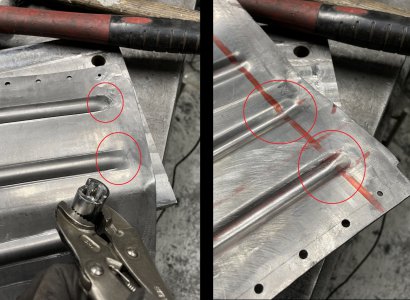

I "coined" all the beads as shown in the previous photo. Never tried this before but got inspired by some youtube video.

Gave it a quick "hack level try" by grinding out a socket and cutting half off as I didn't feel like starting the lathe and making tools.

The socket was surprisingly soft and quickly deformed from the hammer blows but it did it's job on the sheet.

Even tho the result is far from perfect I still prefer it to the "un-coined" beads that just smear back into the main sheet where they end.

Definitely need to make a proper tool that's easier to use, with this setup I was trying to hold the sheet with my hip, socket with left hand and hammer with my right hand, hence all the weird marks where they shouldn't be.

And this is what the inside looks like now.

I didn't pre-stretch before I beaded them which caused a lot of warping, definitely need to pre-stretch when you've already meticulously shaped the pieces to fit perfectly...

Caused quite a bit of work afterwards with hammer and "hand manipulating" to get it to fit. It's not as good as it was before but still fits in pretty OK.

Most of the clecos sit in 3mm holes in both plate and frame and only required a little force to get all of them in.

Pretty stoked about finally having a little bit of floor after almost 3 years or something.