- Joined

- Sep 1, 2023

- Messages

- 468

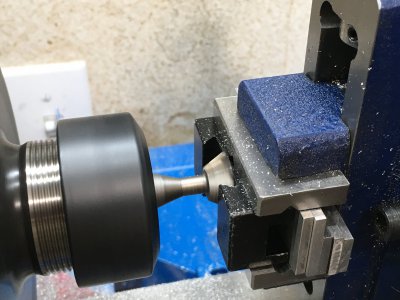

When you get the collets, make sure you check all the slits and the bore for any burrs and manufacturing debris; because of the design of ER collets, any muck or burrs in the slits can lead to inaccuracy.

A clean and tidy ER collet is a happy collet.

A clean and tidy ER collet is a happy collet.