- Joined

- Jun 17, 2012

- Messages

- 2,220

I never would have guessed a 60 grit wheel would give such a nice finish, but I guess the fine feed makes up for the course wheel. I gotta start cutting back on my coffee consumption at night. Lately I've been rattling all kinds of projects around in my brain before I fall asleep.

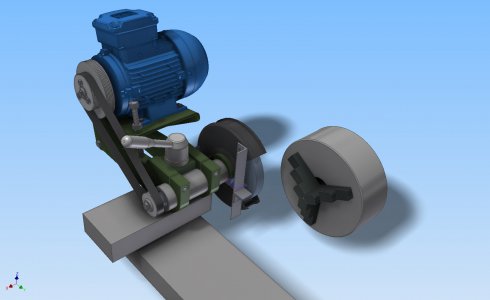

On another note, I just ordered the bearings for the Rotary Broach build. I'll be doing a how-to on it once the bearings come in.

Marcel

On another note, I just ordered the bearings for the Rotary Broach build. I'll be doing a how-to on it once the bearings come in.

Marcel