- Joined

- Nov 29, 2020

- Messages

- 53

Howdy all,

I’m look to gather some outside perspective on a welding/working table I found. I have wanted to buy it the moment I saw it, and that’s part of the problem. I’m seeing things one way due to the super cheap price. The price breakdown is about $.24 a pound for those wondering.

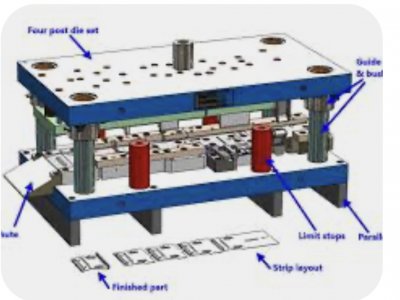

I would really appreciate others thoughts on if I’m asking for a big headache with this thing or tell me I’m nutz if I pass it up. The material of the steel plate is unknown and is way overkill at 2 and 3/4” thick and about 33” wide x 86” long and weighs approximately 2,000lbs. The plate was placed on a metal frame table that supports it fine and is about 3ft tall. I’ll post a picture as well.

Now that you know specs about it, let me explain what my uses are and the place it’ll be going. My main use will be for hobby type use welding/fabrication, assembling stuff, and mounting things like a metal shear, bench vise, and possible a 2x72 belt grinder when it’s done (and indoors). For the time being and probably the next 1-2yrs (hope to build a shop area eventually and having the bench indoors then), the table will be located outside on lightly graveled uneven ground, so once it’s on the ground it will be essentially stationary. The owner will load it in my truck with a forklift and I’ll have no issues hauling it home. Unloading will be a cherry picker and chain kind of thing.

So folks, am I asking for more problems than it’s worth? Is there some serious flaws that I’m not seeing because I’m listing about this hunk of steel With the price of steel, finding another suitable table material like a 1/2” plate is out of the question and doesn’t make sense for the $$ they want for even half a 4x8 sheet. At this price point, I’m struggling to see past this as a cheap supply of steel if nothing else. Thank you in advance to all that provide input, pro or con.

With the price of steel, finding another suitable table material like a 1/2” plate is out of the question and doesn’t make sense for the $$ they want for even half a 4x8 sheet. At this price point, I’m struggling to see past this as a cheap supply of steel if nothing else. Thank you in advance to all that provide input, pro or con.

I’m look to gather some outside perspective on a welding/working table I found. I have wanted to buy it the moment I saw it, and that’s part of the problem. I’m seeing things one way due to the super cheap price. The price breakdown is about $.24 a pound for those wondering.

I would really appreciate others thoughts on if I’m asking for a big headache with this thing or tell me I’m nutz if I pass it up. The material of the steel plate is unknown and is way overkill at 2 and 3/4” thick and about 33” wide x 86” long and weighs approximately 2,000lbs. The plate was placed on a metal frame table that supports it fine and is about 3ft tall. I’ll post a picture as well.

Now that you know specs about it, let me explain what my uses are and the place it’ll be going. My main use will be for hobby type use welding/fabrication, assembling stuff, and mounting things like a metal shear, bench vise, and possible a 2x72 belt grinder when it’s done (and indoors). For the time being and probably the next 1-2yrs (hope to build a shop area eventually and having the bench indoors then), the table will be located outside on lightly graveled uneven ground, so once it’s on the ground it will be essentially stationary. The owner will load it in my truck with a forklift and I’ll have no issues hauling it home. Unloading will be a cherry picker and chain kind of thing.

So folks, am I asking for more problems than it’s worth? Is there some serious flaws that I’m not seeing because I’m listing about this hunk of steel