- Joined

- Jan 20, 2016

- Messages

- 602

shooter 123456,

Very good. I'm active duty military with a background that provided me with a lot of experience with factory cans and then I started machining after taking classes at my local tech school. I've had students as well as hobbyists ask me about making suppressors. So not a big deal as long as we educate people to keep everyone out of trouble.

I've used AAC, Gemtech, KAC, SWR, and AWC cans on various rifles (select-fire & precision), sub-guns, and a few pistols. Things I liked and disliked about every model. For home builds I like good knurling and spanner pin holes on the end caps. I like the way Griffin adds cut outs on the end of the tube itself to provide a grasping point. Having multiple endcaps for different center-fire calibers is the way to go if you are making a multi-caliber can. But not for .22.lr. I recommend a dedicated .22 l.r. only can. Much lighter weight wise for construction.

New users are shocked at how much fouling/blowback they get in their AR style rifles the first time they use a can. Each can is different. So don't burn thru a bunch of magazines to find you have an unacceptable level of fouling & buildup. I've seen some baffles almost welded together from the fouling. On that note it is worth the time to polish your baffles and the inside of the tube as much as possible. I also use Bostik brand anti-seize grease on the threads of the endcaps.

Shooting a select-fire gas operated gun will increase the cyclic rate (i.e. boost effect). Number your inner baffles! Helps with re-assembly and rotating them so they wear more evenly.

Is the .308 a semi/auto or a bolt gun? If you make a dedicated can for a bolt gun you can get away with a easier to machine material for the blast baffle. For all around use I would use 17-4.

Wow... I really wish I came here to ask questions before I started. I would have come out with a much much better can. I really appreciate the wealth of knowledge you guys all have to share.

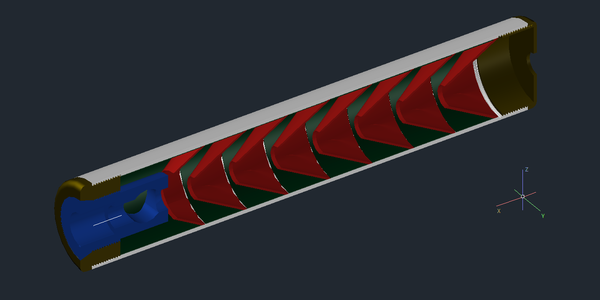

Here is the original design that came to after a couple rounds of revisions with the guys at silencertalk:

The idea was that the muzzle brake would be a sacrificial blast baffle since I can make and replace those as often as I want. From what I understand, the erosion of the blast baffle is primarily around the bore hole as thats where the unburnt pressurized powder is sent and essentially sandblasts it. I am far from an expert though so I have deferred to the judgement of those that are more experienced. The plan was to go with 17-4 for the blast baffle, but I haven't been able to find any in small amounts and I haven't been able to justify the cost. At this point, plan A is to use the 303 I have on hand and if I have erosion problems in a few years, there is an 07/02 about half an hour from me that can turn me a new one out of 17-4 and destroy the old one.

Having multiple endcaps for different center-fire calibers is the way to go if you are making a multi-caliber can.

I was told this was a no go. Since the ATF considers every part of a silencer a silencer in itself, any extra parts would consitute having an extra silencer. I was told manufacturers had to get specific permission for each design and home builders were not allowed that exemption. If that isn't true, I would love to turn an extra end cap for .556 to improve their performance on the ARs.

New users are shocked at how much fouling/blowback they get in their AR style rifles the first time they use a can. Each can is different. So don't burn thru a bunch of magazines to find you have an unacceptable level of fouling & buildup. I've seen some baffles almost welded together from the fouling. On that note it is worth the time to polish your baffles and the inside of the tube as much as possible. I also use Bostik brand anti-seize grease on the threads of the endcaps.

I was told to expect that with my first one and it is very true. 100 rounds suppressed through an SBR is dirtier than 1000 rounds through an unsuppressed 16" rifle. I couldn't believe just how much dirtier they ran but they are a mess. The gas in the face is a pain in the butt too. I have been sitting on ways to completely seal the upper so gas only vents through the ejection port and out the side of a gas buster. I keep putting that off because there are other things I want to do first... Regarding the fouling and build up inside the can, a thread on silencertalk said that was unavoidable and people just dip their suppressors when they seize up and its no big deal. I figured that was just part of using suppressors.

Shooting a select-fire gas operated gun will increase the cyclic rate (i.e. boost effect). Number your inner baffles! Helps with re-assembly and rotating them so they wear more evenly.

Is the .308 a semi/auto or a bolt gun?

I wish select fire was something I had to consider with this suppressor... Maybe one day if that registry is opened back up or I do very well when I finish school. Heres to hoping.

I hadn't thought to number the baffles. My plan was to measure them once machining was finished and stack them by thickness so the strongest are in the rear and the thinnest are in the front. I was going for .065" with them and then with several lightened them up to the .050" range. Is there a way to could recommend to number them that will stand up to cleaning and the beating everything inside will take?

The .308 is a bolt gun. 24" Savage 10 FCP-SR. Its a hoot and a half to shoot. I anticipate the new suppressor will be used mostly on the .308 and a 300 blk SBR using 230 gr cast and coated subsonic ammo. Neither of those are supposed to be particularly tough on cans. If it goes a .556, it will probably be used on my match gun which I have shooting 55 gr FMJ at about 2500 FPS so there is very little pressure in that one as well.